New Solution for Monitoring Liquid-Based Processes

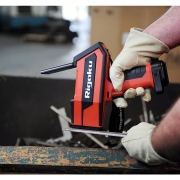

At the 8th World Conference on Sampling and Blending (WCSB8) in Perth (Western Australia), PANalytical, an international supplier of analytical X-ray instrumentation and software, has announced the new Epsilon Xflow system.

As reported, this new on-line solution is made for the continuous analysis of the elemental composition of any liquid, providing real-time feedback from a production process.

The Epsilon Xflow can be incorporated in many different process streams in a wide range of industries such as mining and metals or the production of petrochemicals, polymers or food, PANalytical gave account. “Predefined conditions can be closely monitored, enabling an immediate reaction to any change, in this way avoiding waste and unnecessary expenses.” For example in the petrochemical industry the system could analyze sulfur in fuel even at concentrations lower than 10 mg/kg at many stages of the production process. At the same time low concentrations of vanadium and nickel, which may be harmful to the refinement process, can be determined. “Industries will be able to closely check their waste water for hazardous compounds; a task becoming increasingly important with the obligation to comply with stringent environmental regulations,” the company emphasized.

According to the information, the analytical core of Epsilon Xflow employs proven energy dispersive X-ray fluorescence (EDXRF) technology, which is robust and non-destructive with low detection limits and highly accurate and reproducible analysis results. Elements from Sodium up to Americium at concentrations from a few ppm to 100 percent can be analyzed. “Almost any liquid can pass through the flow cell across the detector which has a leakage protector in place,” the provider says. “The system can be tailored to any customer’s needs with optional sample conditioning and common interfaces to manufacturing execution systems.”

About PANalytical

PANalytical employs over 1,000 people worldwide; the company’s headquarters are in Almelo, the Netherlands. Its customers can be found in virtually every industry segment, from building materials to pharmaceuticals and from metals and mining to nanomaterials. The combination of its software and instrumentation, based on X-ray diffraction (XRD), X-ray scattering, X-ray fluorescence (XRF) and near-infrared (NIR) spectroscopy as well as pulsed fast thermal neutron activation (PFTNA), provides the company’s customers with information on their materials and is applied in scientific research and industrial process and quality control.

PANalytical also provides a variety of instruments and tailored solutions to satisfy regulated activities and support environmental investigations and research alike. Typical applications include waste material analysis, biomass elemental analysis, soil and sludge elemental analysis (heavy metals) and asbestos mineral identification and quantification.

Photo: PANalytical

GR 32017