New Recycling Plant for Contaminated Steel Scrap

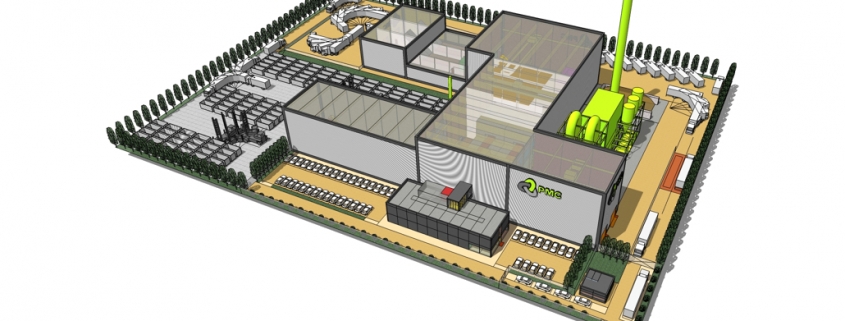

Dutch Purified Metal Company (PMC) starts the construction of the plant in Delfzijl, The Netherlands.

In July this year, Purified Metal Company has completed the financing for the construction of a large-scale state-of-the-art processing plant that is to recycle contaminated steel scrap (for example asbestos and other toxic materials). According to Berlin-based EIT RawMaterials (initiated and funded by the European Institute of Innovation and Technology), which has supported the established SME as a start-up, PMC is the “first company in the world with an environmentally friendly and economically feasible method to recycle contaminated steel scrap into high-quality raw materials for the steel industry”.

After realizing the first factory in the Netherlands, Purified Metal Company aims to roll out the innovative and patented process for the recycling of contaminated steel scrap in the rest of Europe and the world. The company expects that the factory will be operational by July 2020 at the latest.

Circular solution

The solution for recycling contaminated steel was developed together with UK-based waste-to-product company Renewi plc, which will exclusively collect and transport contaminated steel directly to PMC’s new recycling facility in the Netherlands. “As asbestos was frequently used in the construction of buildings, plants, ships and housing between 1960 and 1993, the lifespan of many of these structures will soon be coming to an end, resulting in a relatively large amount of asbestos-contaminated steel scrap,” Renewi informed in May this year. “As asbestos is harmful for health, its remediation is usually an extremely labor-intensive and expensive process with any hazardous materials needing to be disposed of in a safe and controlled way.”

As reported, PMC’s facility will combine “innovative processes with existing techniques originating from other industries”. During the process, the fibrous parts of the asbestos would be destroyed, ensuring that it is no longer hazardous. “In addition, other hazardous substances contaminating the steel, such as chromium-6 and mercury, are captured or neutralized”.

“The process prepares steel for reuse in the form of Purified Metal Blocks (PMBs) which are raw materials typically used in the manufacturing industry that can be made to certain specifications, dependent on the requirements of the end user,” PMC assured. “The production of PMBs is safer, more affordable and more efficient than current remediation techniques.”

The collaboration between Renewi and Purified Metal Company “will have benefits for both customers and the environment through the recovery of valuable raw materials from complex waste streams and the reduction of carbon emissions,” the two companies emphasized.

_____________________

About Purified Metal Company

PMC was founded by a group of shareholders who have combined expertise and form the basis of the innovation in the field of recycling of contaminated steel scrap. By PMC’s own account, they were able of transforming the innovation into a process in which hazardous raw materials can be converted into usable raw materials complying with the end of waste criteria of the European Community. According to the company, existing knowledge and expertise is enhanced through the collaboration with highly qualified partners in a consortium.

_____________________

www.purifiedmetal.com/en

www.renewi.com/en

www.eitrawmaterials.eu

Source: PMC

GR 3/2018