Valdi Has Finished First Battery Recycling Run

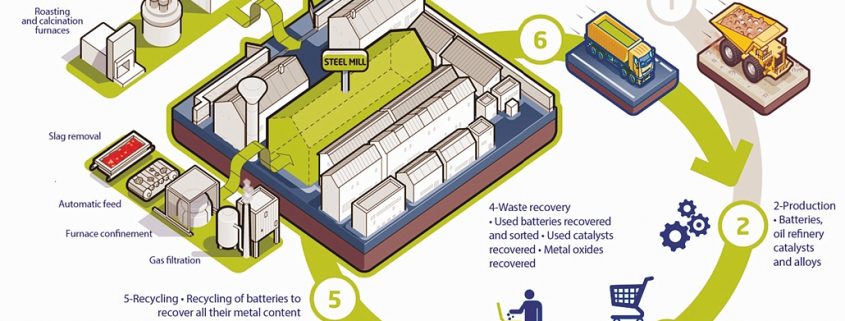

From the end of 2017, Valdi (a subsidiary of Eramet Group) will offer Europe’s biggest processing capacity based on pyrometallurgy: It will have an annual processing capacity of 20,000 tons of batteries, 10,000 tons of spent oil catalysts and 8,000 tons of metal oxides.

According to the company, pyrometallurgy is “the only technology that guarantees that 100 percent of metals in spent batteries are recovered, with zero landfilling”. In February this year, 200 tons of batteries were treated to finalize the process. According to the information, this first wave of battery recycling is perfectly in line with the project’s orientations. The next run, planned for the second half of March, would enable the plant to ramp up processed volumes, with a high-speed steel run, the site’s other production, also on the schedule.

Located in Commentry, Allier (France), Valdi is – according to Eramet – a unique industrial setup. The metals contained in batteries, oil catalysts and metal oxides can all be recycled on a single site. This specificity, combined with waste valorization, makes Valdi a solution provider and a major participant in France’s competitiveness in sustainable development, the company is convinced.

In a brownfield industrial site, Valdi is helping to build a French and European channel for recycling batteries under the circular economy principle, maintain industrial jobs in central France and meet major European challenges. Since early 2016, the European obligation to collect spent batteries increased from 25 percent to 45 percent, with the corresponding need for processing capacity.

www.eramet.com/en/valdi-recycling-catalysts-batteries-and-metal-oxides

Graphic: Valdi

GR12017