Refrigerators: New Plant Concepts Detect Blowing Agents

The share of halogen-free refrigerants and blowing agents is increasing in the disposal of cooling devices.

In Europe, since 1996 no refrigerators have been produced with halogen-containing refrigerants and blowing agents (CFCs). Accordingly, the share of alternative refrigerants and blowing agents is rapidly increasing during disposal. In most German waste disposal plants, the share of halogen-free refrigerators has already increased to more than 50 percent. In southern European countries, this share is already over 70 percent. Within the next 5 years, this share can rise to 90 percent. Conversely, it is expected that 5-10 percent of halogenated (CFC) end-of-life refrigerators have to be disposed during many years to come.

Selective treatment of end-of-life refrigerators

Especially in the field of corpus treatment (step II), it makes sense to think about new plant concepts, since the treatment of refrigerators with halogen-free blowing agents will be more expensive in conventional plants than the treatment of the halogen-containing refrigerators. This is due to the combustibility of the alternative, halogen-free blowing agents (pentanes).

Detection of blowing agents with the support of robots (Photo: URT Umwelt- und Recyclingtechnik GmbH)

Analytical detection of blowing agents in polyurethane foam

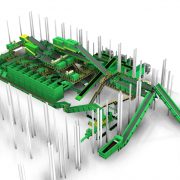

URT Umwelt- und Recyclingtechnik GmbH has been working on concepts for reducing operating costs for years. The core technology is the unequivocal selection between halogen-free and halogen-containing insulation foams. This is the basis for a later selective treatment of the refrigerators. For this purpose, openings are made on the corpus and on each door of the respective end-of-life refrigerator and gas samples are taken, which are subsequently analyzed automatically.

Direct burning of halogen-free blowing agents

Usually, blowing agents are recovered and liquefied at refrigeration equipment plants. The CENELEC standard was the first regulation that described a step III treatment in EN 50574. This is the direct burning of blowing agents from the polyurethane foam. Direct combustion of halogen-free blowing agents is significantly simpler than the combustion of halogen-containing blowing agents from polyurethane foams. Due to high suction quantities for detection of blowing agents the explosion limit can fall down significantly by dilution. The use of nitrogen for explosion suppression is then no longer necessary. The high exhaust volumes reduce diffuse losses of blowing agents. Emission regulations at the plants and in the exhaust air can be definitely under-run.

Reference plant in Germany

A cooling device recycling facility, which is operating according to this plant concept, has already been installed for the company ALBA Electronics Recycling GmbH in the first quarter of 2017.

An existing plant is continuing as well as the disposal of CFC-containing refrigerators. The new plant of the company URT Umwelt- und Recyclingtechnik GmbH is intended for halogen-free end-of-life refrigerators.

Photo: URT Umwelt- und Recyclingtechnik GmbH

GR 32017-Advertorial