PICVISA: Transforming the Recycling Industry with the new ECOPICK 2.0

Three years after installing the first ECOPICK unit in a sorting plant, PICVISA launches ECOPICK 2.0. The company has introduced changes to the robot that is transforming the recycling industry in line with its mission and innovative vision that has positioned itself as a leading player in the sector.

Easy to instal and mantain

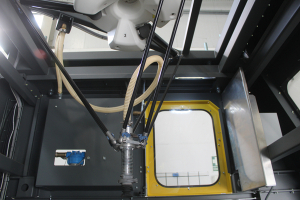

One of the most striking aspects of the ECOPICK 2.0 in terms of design is its modularity: vision module, upper structure and lower structure. The structure (upper structure, lower structure and vision components) has a symmetrical design, which makes it easy to install and flexible to integrate. This means that the suction, display and maintenance point can be arranged and installed in various combinations.

Another highlight of this advanced equipment is the containment of the luminous area, providing optimum stability of the recognition inside the machine, regardless of the lighting conditions of the environment.

The modular structure of the equipment also presents advantages for its maintenance: easy, accessible and centralised in the operator‘s area, with the possibility of remote connection to the machines and measurement of the main performance parameters. ECOPICK 2.0 is designed for operational comfort, including space and access to the hoppers inside the machine. In addition, the change of suction tube has been simplified, eliminating machine downtime.

In addition, the more complex safety systems have also been reinforced, thereby reducing the risks at all stages of the equipment‘s operation.

New gripping systems

In relation to the modular setup of the new robot, the upgrade of one of PICVISA’s flagship units also improves flexibility in the handling of materials, with different robot models and gripping systems to adapt to the requirements of the objects to be sorted. Among others, the following gripping systems are available: single suction cup, very effective with small containers and coffee capsules, double suction cup stirrer, designed for the recovery of light containers of different sizes, single electromagnet, for the recovery of metals, base plates and WEEEs, mixed suction system plus effective electromagnet for the purification of ferrous material flow.

Due to the versatility of the different gripping systems, customers can focus on positive (sorting) or negative (quality control) selecting, depending on their needs. This is something that ECOPICK already offered, but which has been (and will continue to be) expanded in the new version.

Better technology, more information

ECOPICK was presented as a robot with artificial intelligence that used Vision and Artificial Intelligence to automate sorting and triage in recycling plants. The advance offered by PICVISA with ECOPICK 2.0 is a more efficient exploitation of the information produced by all the activity of the units.

The client has access to the visualisation of all extracted data as well as the possibility to customise the information with the help of our data analysis experts.

Optical equipment and Artificial Intelligence pave the way for more consistent detection rates, providing recycling plants with a horizon full of data. It is easy to deduce that plants using AI technology will also use data to increase their competitiveness in an increasingly changing and demanding market.

In response to this new need, through data analysis we offer our clients the possibility of increasing the productivity and profitability of the plant. Transforming data into valuable information, combining Artificial Intelligence technologies, Artificial Vision and Data Mining.

In short, there are many advantages:

- Saving time and resources on characterisations

- Possibility to plan intervals between maintenance services

- Control of energy consumption

- Remote monitoring of performance

- Cost control

- Easy monitoring of process parameters

- Optimisation of production

Sales modalitites

With ECOPICK 2.0, PICVISA reaffirms its positioning as a strategic technological partner in the business of its customers that it has been working on in recent years. A vision with which the company wants to be much more than a one-off supplier, providing constant support, with a commitment to keep equipment up to date, without technological obsolescence.

To make this possible, the company offers up to four different sales modalities, from standard sales to leasing and hire-purchase, designed to achieve an immediate result, in constant evolution and improvement, constantly adapting to the market, diluting the impact on the company’s cash flow.

The consequences of this strategic business positioning are more than positive: stable, long-lasting, trusting relationships with effective results.

In short, ECOPICK 2.0 is based on the company’s own experience and learning and, together with its new range of sales possibilities, will be a big step towards success. This is what Luis Seguí, managing director of PICVISA, remarked at the launch of the new robot:

“With the ECOPICK 2.0 we reflect all the learning from the last 20 years in waste and the experience we have gained with robots. It‘s been more than three years since the installation of our first in-plant robotic unit and we are now here to launch the ECOPICK 2.0: modular design, maintenance optimisation, increasingly sophisticated and extensive databases, possibility to combine RGB, NIR, 3D technologies … And not only that, but we offer the possibility to the customer to buy a service instead of a machine: less impact on the financial structure of the company, equipment that always includes the latest updates and with up to date maintenance.”

(Published in GLOBAL RECYCLING Magazine 2/2021, Advertorial, Page 51, Photo: PICVISA)