Wet Processing Provider CDE Realized Its First Solution in Belgium

Ireland-based company CDE has commissioned its first solution in Belgium for family-owned business De Bree Solutions as it upgrades its 20-year-old equipment range.

Founded in the 1970s, the Belgian company is a sewage and waste collection service provider. Having expanded its focus over the past five decades, De Bree Solutions is active in industrial cleaning, green processing, soil cleaning, soil remediation, waste management, water purification and sewer renovation throughout Belgium, Netherlands and France. At the turn of the millennium – as a result of evolving environmental legislation – De Bree Solutions invested heavily in the latest recycling technologies of the day. Therefore, the company established soil remediation and water purification facilities in Maldegem and opened three new sites in Ostend, Eke and Schoondijke where raw materials are recovered from contaminated and inert waste streams.

Once again, the company has invested in the latest waste processing technologies, entering a period of business growth and sustained demand for its product range.

CDE solution

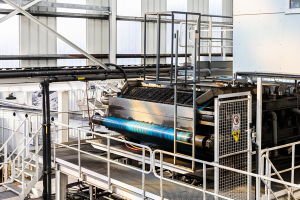

The solution proposed by CDE included its AggMax, EvoWash and CFCU systems to process highly variable feed material including organic waste, contaminated soils containing metals, cyanide and oil; construction, demolition and excavation (CD&E) waste; and road sweepings.

CDE’s AggMax technology “is engineered to operate in the toughest of conditions to maximize product yield from the most abrasive of feedstocks,” the Irish business expert underlined. “Its versatile design incorporates five processes on a single and compact portable chassis, including pre-screening, scrubbing/attrition, sizing, contaminants removal and stockpiling.” The heavy-duty AggMax could process challenging CD&E waste material containing large quantities of organic and other inert physical contaminants into high-value materials suitable for a variety of applications in the construction industry.

As reported, fine material is processed by CDE’s signature EvoWash technology. A compact, modular sand washing system, the EvoWash screens and separates the smaller sand and gravel fractions through an integrated high-frequency dewatering screen, sump and hydrocyclones. “Incorporating CDE’s patented Infinity Screen technology, the EvoWash offers optimal dewatering results which enables materials processors to produce a range of high-quality sands that are market-ready straight from the belt.”

Furthermore, the CFCU technology would allow the effective separation of two materials of different relative densities. “With a variable cut (separation) point, it offers greater control over sand classification providing complete flexibility for the production of various end products and the removal of lightweight contaminants from the fine material fraction”, the information said.

400 tons per day

Since the seamless integration with the existing plant setup, CDE’s solution has almost doubled processing capacity at the Maldegem site. According to Yves Dupont, Managing Director at De Bree Solutions, the target is 400 tons of sand and stone per day in one production. “Thanks to CDE, we now have that capacity there which will help us keep up with growing demand.” Both the sand and aggregate fractions would pass through the newly commissioned equipment, which has increased capacity and improved output quality. Washed sand processed by the CDE solution is being used for over 90 percent of concrete produced by De Bree Solutions for underground works. The aggregate output is used for various applications, including concrete products, drainage and other construction-related applications.

www.cdeglobal.com

www.debree.be

(Published in GLOBAL RECYCLING Magazine 3/2021, Page 22, Photo: De Bree)