Teknor Apex: NEW Monprene TPEs

Teknor Apex announces NEW Monprene® TPEs that contain 25-35% recycled content – meeting consumer and regulatory demands for higher levels of recycled content in products. This significant added value helps brands achieve their sustainability goals.

Trusted by major consumer brand owners and processors alike, Monprene® thermoplastic elastomers (TPEs) allow designers more flexibility and give manufacturers peace of mind. Now, more than ever, that peace of mind includes being environmentally responsible. Teknor Apex is pleased to introduce a new series of TPEs, the Monprene® RX CP-15100 series, containing 25 to 35% recycled content; a significant added value that helps brands achieve their sustainability goals.

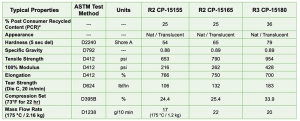

Monprene® RX CP-15100 Series is currently available in 55, 65, and 80 Shore A, but the hardness can be tailored to specific customer requirements. The “R” prefix denotes recycled content. * Percentage of Recycled Content = Mass of Recycled Material in Compound / Total Mass of Compound x 100 (Graph: Teknor Apex)

The Monprene RX CP-15100 series, formulated with PCR (Post Consumer Recycled) content, promotes a circular economy while decreasing reliance on virgin fossil-based resources and energy. This offering allows brands to meet consumer and regulatory demands for recycled content within their products. These TPEs are available globally and manufactured around the world with locally sourced raw materials procured to exacting specifications – turning local waste into resource. Unlike competitive TPEs with recycled content, available in black only, these materials are delivered in a consistent light, natural color, similar to their prime offsets.

A Sustainable Option for a Variety of Products

The Monprene RX CP-15100 series is available in standard grades from 55 to 80 Shore A, and can also be tailored for a customer’s specific requirements. These grades are designed for injection molding applications, including overmolding onto polypropylene. These materials perform and processes like prime TPE and are ideal for personal care products*, lawn & garden tools, writing instruments, appliances, sporting goods and dunnage. The PCR content is sourced from waste diverted from households, or commercial, industrial and institutional facilities. The use of PCR content contributes toward a circular economy and creates demand for consumer recycling programs. Not only does Monprene RX reduce plastic waste by incorporating it into the compound, but products made from Monprene RX are still fully recyclable at the end of the product’s life.

“Because people and our planet are what matter at Teknor Apex, this specialty TPE is an important part of our sustainability program. We actively look to increase the sustainability of our products, while reducing the environmental impact of our manufacturing operations. Our focus includes improving energy efficiency, reducing water consumption and diverting waste from landfills,” said Jonathan Plisco, New Business Development Manager.

Monprene RX CP-15100 Series TPEs are manufactured according to the standards of ISO-9001 and ISO 14001 in the USA, Singapore and Germany, with strict formulation control and traceability. “This introduction represents the first of several sustainable product launches slated for this year – that include other types of recycled content, bio-based raw materials, and carbon negative additives. We are actively collaborating with various partners in the supply chain, with continued growth in our portfolio,” adds Plisco. For more information, please contact the company at tpe@teknorapex.com

* Monprene R2 CP-15100 Series TPEs are not intended for applications requiring food contact regulatory compliance.

Source: Teknor Apex (Pawtucket, RI USA, March 23, 2022)