Would You Drive a Car Built from Recycled Materials?

Norwegian industry is shifting towards a greener future. But what does the transition to a greener economy really mean for industry and consumers?

The Norwegian University of Science and Technology (NTNU) explained the requirements, illustrating with an example: cars.

When wrecking a car, usable parts are taken out and reused. Materials that can be remelted are sent to recycling. Many car parts contain valuable metals (including the battery, which has rare metals) that hold great potential for a new life. The degree of recycling depends on how the car parts are produced.

The green shift means that we slowly but surely need to get used to the idea that the products we buy are not “new” but consist of materials that have been given new life through recycling. The latest report from the United Nations’ Intergovernmental Panel on Climate Change (IPCC) is crystal clear that immediate and major reductions in greenhouse gas emissions are necessary to achieve the Paris Agreement goal to limit the earth’s temperature increase to 1.5 degrees celsius.

For industry, this means transitioning to manufacturing low-carbon products. More products need to be recycled. Moreover, production needs to be adapted to a world in which things are reused, either as the same original product type or remelted and reused for new purposes. The goal is to maintain the value of products, materials and resources for as long as possible. That aligns with the principle of a circular economy. The idea is that all manufacturing should consider the product’s lifespan and recycling possibilities. Another important factor is high product quality. We need products with a long shelf life that do not need to be replaced often. Longer product life will contribute to the green shift.

The transition to greener processes in the metal industry has been going on for some time already. However, the awareness of the great potential for further reducing emissions is now growing. Norwegian (and international) metal-based industries must increasingly comply with national and international rules and requirements for greater use of recycled metal in their materials and products. Better systems and routines for collecting and sorting scrap metal are important, but it is also critical and necessary to develop new metal alloys and products that are designed to be recycled.

New technologies (process and material solutions) and innovations enabling greater reuse of scrap metal are essential in the green shift. For example, 75 percent of all aluminum produced in the world is still in use and represents a major resource for the respective industry, both in replacing and supplementing the primary production of aluminum. Remelting requires only five to seven percent of the energy required for primary aluminum production.

Finding new and greener manufacturing methods requires a lot of new knowledge. Research and industry need to work hand in hand for a rapid green shift. Funding schemes for research in Norway (e.g. the Research Council of Norway’s “Green Platform”) and internationally (e.g. the EU’s “Green Deal”) are now aiming at projects that have sustainability as their fundamental objective.

Innovative measures will facilitate increased knowledge. Ensuring that all the new knowledge is used in the industry and becomes part of the circular economy is also key. To this end, research organizations and the industry must collaborate closely.

Center for research on physical metallurgy

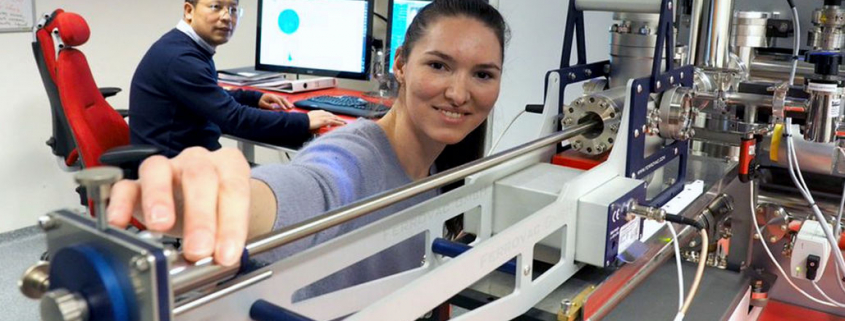

The Norwegian University of Science and Technology, NTNU and SINTEF, Scandinavia’s largest independent research institution, have established SFI PhysMet, a center for research on physical metallurgy where researchers and industry partners work closely together. The center is one of the Research Council’s centers for research-based innovation (SFI).

Physical metallurgy can be defined as the “art” of making useful products from metals. The field encompasses the study of the properties of metals and alloys, such as mechanical strength and forming properties. The overarching goal of SFI PhysMet is to help Norwegian metal-based industries shift to more sustainable materials, processes and products.

SFI PhysMet collaborates with the automotive industry to produce car parts with lower CO2 footprints. The center is also working on creating sustainable metal-based solutions. These are important for developing offshore wind turbines, the construction of large bridge structures that can replace the ferry on the E39 highway between Trondheim and Kristiansand, and new processes for making materials and alloys better suited for recycling and recovery.

The interaction between research and industry is essential for shifting to greener technologies. In the end, however, it is consumers who will make use of all the “green” products. Down the road, we may all be driving cars produced completely from recycled materials.

We can probably expect the recycled products to be, at least, as good as today’s products. The difference is that the new production methods will contribute to the green shift and a safer future for our earth, NTNU wrote.

(Published in GLOBAL RECYCLING Magazine 1/2022, Page 10, Photo: Per Henning, NTNU)