Turning Sewage Sludge into Fuels and Hydrogen

Climate change and energy shortages spur innovations.

In August, USA-based financial, software, data, and media company Bloomberg reported that Northwest Europe “is forecast to begin a perilous winter with historically low amounts of diesel, a fuel that powers vast swaths of the economy”. The region’s stockpiles of road diesel, heating oil and other diesel-type fuel were set to shrink this November “to the lowest level in data that goes back to the start of 2011”, wrote author Jack Wittels, referring to information from global research and consultancy group Wood Mackenzie Ltd. Likewise, market research company Insight Global had figured out that in the Amsterdam-Rotterdam-Antwerp oil-trading hub inventories were at the lowest level for the time of year since at least 2008, he gave account. “Europe is structurally short of diesel-type fuel, regularly receiving cargoes from overseas. That natural shortage could become more of a problem early next year when an EU ban on seaborne imports from Russia – currently the continent’s single-biggest external supplier – is set to take effect.” This was just one part of a broader energy crisis that had “engulfed the continent following Russia’s invasion of Ukraine, sending the prices of natural gas and electricity soaring and fanning inflation”.

Energy sources from sewage sludge

A way out of this situation – especially in Europe – could be, inter alia, the European project TO-SYN-FUEL aiming at the production of green hydrogen, diesel and gasoline from sewage sludge. Furthermore, if successful, it could be a showcase example for future sustainable investment and economic growth across Europe, the project consortium with 11 partner organizations is convinced. Horizon 2020, the EU’s research and innovation program funded the undertaking, which ended after more than five years in September 2022.

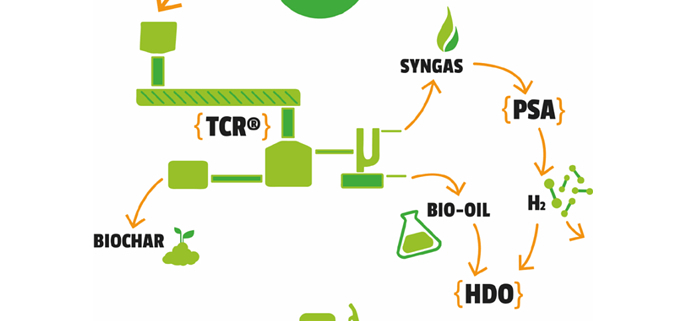

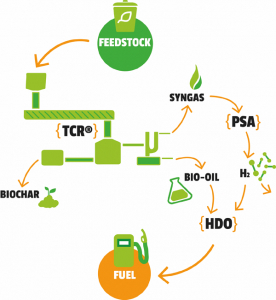

As reported, TO-SYN-FUEL implements a new integrated process – combining Thermo-Catalytic Reforming (TCR), with hydrogen separation through pressure swing adsorption (PSA), and hydrodeoxygenation (HDO) – to produce a fully equivalent gasoline and diesel substitute (compliant with EN228 and EN590 European Standards) and green hydrogen for use in transport. “This project will be the platform for deployment of a subsequent commercial-scale facility. This will be the first of its kind to be built anywhere in the world, processing organic industrial wastes directly into transportation grade biofuels – fuels, which will be a demonstration showcase for future sustainable investment and economic growth across Europe,” one can read on the project website (www.tosynfuel.eu). The initiative would mark “the first pre-commercial scale deployment of the technology” processing up to 2,100 tons per year of dried sewage sludge into 210,000 liters per year of liquid biofuels and up to 30,000 kilograms of green hydrogen.

According to an article published in April this year by the quarterly online journal Open Access Government, the first testing campaigns with TCR have shown “a very satisfying performance”. Within more than 500 operational hours, over 200 tons of dried sewage sludge had been converted into 20,000+ liters of TCR oil, Robert Daschner from German Fraunhofer-Institut für Umwelt-, Sicherheits- und Energietechnik UMSICHT stated, referring to November 2021. The yield and the quality of the products achieved were within expectations. In the last step of the project, further campaigns were planned to process 12 tons of dried sludge per day and to gain more long-term experience with the technology.

Concerning the overall efficiency of the plant, “it is known from pre-tests of small-scale experiments that up to 90 percent of the energy can be transferred from the feedstock to the products, and that around 10 percent of energy from feedstock is needed as heating energy”, Robert Daschner wrote. “Specifically, the liquid bio-oil produced by TCR has a high heating value.”

(Published in GLOBAL RECYCLING Magazine 3/2022, Page 6, Source: TO-SYN-FUEL)