Real-Time Data Visualization to Create New Value

“STEINERT.view” is a monitoring solution for sensor-based sorting machines made by German manufacturer Steinert. The monitoring solution gives users insight into the availability and output of individual machines, allowing them to learn more about the condition of their applications or sorting facility, the firm explained its advantages. “For the first time ever, this detailed machine data is accessible at any time and from any location.”

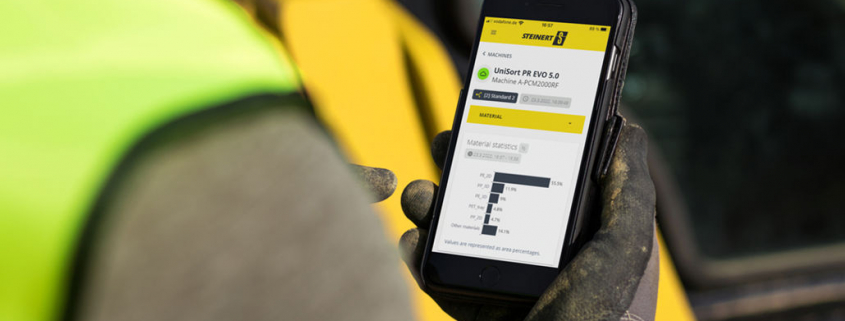

Designed as a mobile-first app, “STEINERT.view” would provide users with a quick overview of the key performance and output data on the move. At the same time, complex process technologies could also be visualized. “Filter functions mean that users never lose track of things and can easily identify areas where problems are arising or potential lies untapped.” As underlined, the monitoring solution can also assist with improvements to sorting performance. Changing the grain size and material distribution can influence the product unit. “Comparing nominal and actual values in a graph reveals where action needs to be taken right away. In this way, the data can be used to visualize the effectiveness of measures so that the user can get close to a machine’s optimum operating point,” the expert for raw materials production and recycling pointed out.

According to the engineering company, “STEINERT.view” resulted from working in close collaboration with customers and extensive testing. The system is available as an app for all common screen sizes on the Apple App Store and Google Play Store for all new sensor-sorting units from Steinert. “Upgrades are available for machines constructed in 2018 and later.”

The solution for sensor-based sorting machines is an IoT platform based on international standards. “The transmission of data is always secured via TLS using the MQTT protocol and data-at-rest is 256-bit AES encrypted, using Microsoft Azure as the cloud service provider,” the company assured. In addition, it had been designed “in such a way that it is not possible to influence production or occupational safety on-site and potential cyberattacks come to nothing”.

(Published in GLOBAL RECYCLING Magazine 2/2022, Page 39, Photo: Steinert GmbH)