Toray Achieved a Breakthrough in Recycling Nylon 66

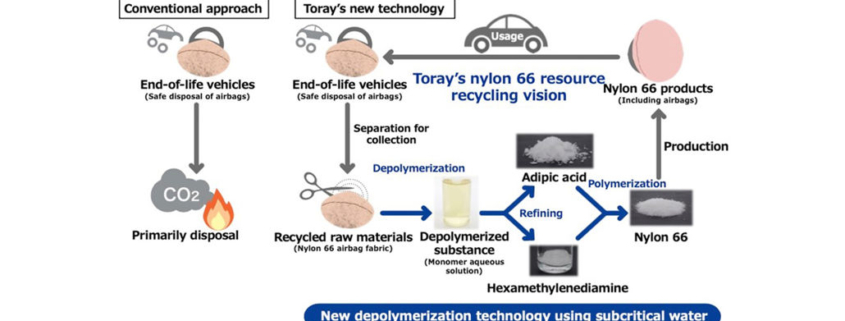

According to Japanese company Toray Industries, Inc., it has deployed a proprietary technology using subcritical water to depolymerize nylon 66 “uniformly and efficiently in just minutes, and recover it as a raw monomer material”. Subcritical water is described as water “in a high-temperature, high-pressure state, just below the critical point of water (374°C, 22 megapascals). It differs from water at normal temperatures and pressures in several ways, such as by dissolving and hydrolyzing organic compounds”.

Toray reports that the demand for nylon 66 is estimated at 100,000 metric tons annually in Japan and 1.3 million tons worldwide. “Its high heat resistance and strength make it essential for automotive and industrial applications. These include automotive textiles such as airbags and tire cords, and plastic components such as radiator tanks, cylinder head covers, and oil pans. Tighter recycling regulations for automotive and other plastics in Japan have made it mandatory to collect used nylon 66-based airbags, making it a promising material for chemical recycling.”

Chemical-recycled nylon 6 for which demonstration efforts are underway, entails recovering a monomer called caprolactam, the information said. “Contrastingly, the process for chemical-recycled nylon 66 requires recovering hexamethylenediamine and adipic acid monomers. Toray drew on its expertise in nylon 6 chemical-recycled technology to assess the depolymerization reaction of nylon 66 in subcritical water. It developed a proprietary technology to suppress side reactions, making it possible to efficiently recover high yields of those two monomers and regenerate nylon 66 through re-polymerization. Using Toray’s technology to make nylon 66 should halve carbon dioxide emissions compared with production from petroleum-based sources.”

The company is particularly focused on automotive materials, establishing technologies to separate other materials in such used equipment as airbags, and technologies to depolymerize nylon 66 and separate and refine monomers. Furthermore, Toray plans “to set up a framework to verify quality and evaluate customers through sample work. It will prepare for full-fledged mass production in around 2030 when stricter plastic recycling regulations are enacted.”

The company intends to develop nylon recycling technologies for both nylon 6 and nylon 66. “It plans to broaden its chemical-recycled technologies beyond apparel and automotive materials to other industrial applications to help create a circular economy and contribute to carbon neutrality.”

(Published in GLOBAL RECYCLING Magazine 2/2025, Page 22, Source: Toray)