Singapore: Researchers Turn Fashion Waste into Multifunctional Material

A research team from the National University of Singapore (NUS) Faculty of Engineering has developed a method to convert cotton-based fabric waste, such as unwanted clothing, into highly compressible and ultralight cotton aerogels.

According to the information provided by the university, aerogels are among the lightest materials in the world and are highly porous with strong absorption capacity and low thermal conductivity. These properties make aerogels highly suitable for applications in areas including oil-spill cleaning, personal care products such as diapers as well as for heat and sound insulation. “While aerogels were first created in the 1930s, this advanced material has not been widely adopted by industries due to its high production cost. Leading aerogel scientists around the world are therefore actively looking at ways to improve the manufacturing and consumption of different types of aerogels. Contributing to this global effort, the NUS team has successfully pioneered the development of aerogels using cotton fibers harvested from textile waste.” As reported, these products can be fabricated within eight hours – this is about 20 times faster than current commercial fabrication processes.

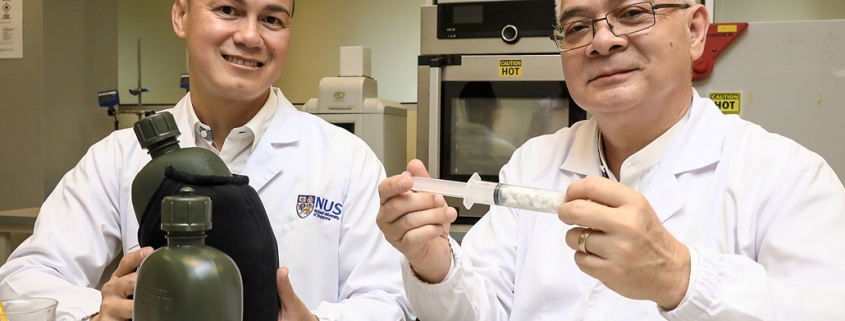

Led by Associate Professor Hai Minh Duong and Professor Nhan Phan-Thien from the Department of Mechanical Engineering at NUS Faculty of Engineering, the research team discovered that the novel cotton aerogels can be easily compressed and that they can also very quickly recover up to 97 percent of their original size when placed in water. Hemorrhage, or the excessive and rapid loss of blood, can often be life-threatening. Hemorrhage control devices are used to exert internal pressure to stop bleeding and promote blood clotting.

The NUS researchers developed highly compressible hybrid cotton aerogel pellets, which are more effective than cellulose-based sponges for treatment of deep hemorrhagic wounds. These pellets – comprising an optimal mix of cotton and cellulose aerogels coated with chitosan – are simple and cost-effective to produce, and they can be easily integrated into a clinical syringe to be used as a hemorrhage control device. The cotton aerogel pellets are also biocompatible; hence they can be safely administered for treatment. “Each cotton aerogel pellet can expand to 16 times its size in 4.5 seconds – larger and more than three times faster than existing cellulose-based sponges – while retaining their structural integrity”, NUS informed.

The NUS research team, in collaboration with DSO National Laboratories, developed also a light-weight thermal jacket to maintain the temperature of ice slurry – crushed ice and liquid water – at 0.1 to 1.0 degree Celsius for more than four hours. The thermal jacket, which weighs about 200 grams, consists of a cotton aerogel layer embedded within commonly used fabrics to provide heat insulation.

The NUS team has filed a patent for the novel cotton aerogels and is now exploring opportunities to work with companies to commercialize the technology.

https://news.nus.edu.sg/press-releases/compressible-cotton-aerogels

Photo: National University of Singapore/AlphaGalileo

GR12018