Ultra-High Performance Concrete Using Waste Clay

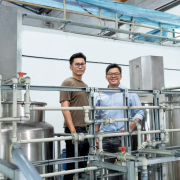

Engineers from the National University of Singapore (NUS) repurpose excavation waste to produce greener and stronger concrete.

Concrete is made up of water, cement and a filler such as sand. The cement industry alone is responsible for about eight percent of the world’s carbon dioxide emissions, and the production of concrete consumes ten percent of the world’s industrial water. Furthermore, the amount of cement produced every two years is more than the amount of plastic produced over the past 60 years.

These considerations led Associate Professor Pang Sze Dai and his team (Centre for Advanced Materials and Structures at the National University of Singapore’s Department of Civil and Environmental Engineering) to focus on the development of greener, more sustainable concretes, intending to reduce this immense impact.

Swapping out scarce sand for common clay

Singapore is undergoing urban development at a rapid rate. Inevitably, this requires vast amounts of concrete, which in turn, creates a huge demand for water and sand – resources that the city-state lacks. But now the team has found a solution to this problem. They demonstrated that they could drastically reduce the amount of sand needed in the concrete mixture by using a common clay material that can easily be obtained as waste from excavation works.

The researchers first obtained excavated waste clay from construction sites in Singapore. Then the material was heated to 700°C to ‘activate’ the clay to enhance the bonding ability in concrete. Afterward, the activated clay was used to replace up to half the fine sand powder typically used in concrete. Finally, the researchers were able to produce “ultra-high-performance concrete (UHPC) – a strong type of concrete that can reduce the size of the structural elements, and potentially reduce the amount of concrete used,” NUS reported.

Upcycling waste clay

“Replacing the fine sand powder is triply advantageous as this material is expensive, has a large carbon footprint and is carcinogenic with prolonged exposure since it contains silica,” the university described the benefits. “In addition, the NUS team also found that replacing part of the sand filler with activated waste clay did not have a significant effect on the strength of the UHPC.” Tunneling and foundation works, which are common in Singapore, would generate a large amount of excavation waste materials. Disposing of waste clay was problematic, as land-scarce Singapore had limited available space for landfill.

The team’s discovery “opens an avenue to transform this waste into a potential resource,” Associate Professor Pang was cited. “Globally, low-grade clay is abundant. Its multi-faceted utilization in concrete as fillers can not only help curtail the carbon footprint of concrete but also reduce the cost of concrete production.” The team is now looking into using waste clay for more concrete applications. Other than the use of waste clay, the NUS research group is also exploring other waste materials to replace the filler in concrete and the usage of seawater and sea sand to reduce the reliance on valuable freshwater and river sand imports in Singapore.

(Published in GLOBAL RECYCLING Magazine 2/2021, Page 43, Photo: NUS)