Handling Batteries from Hybrid and Electric Cars

The Dutch company ARN Recycling exists since 1995 and is mainly involved in the recycling of vehicles. However, since 2008 and due to the introduction of new regulations that came along with the “Battery Management Decree (Bbb)” – which addressed the management of batteries – the firm from the Netherlands is also highly engaged in the recycling of batteries from hybrid as well as electric cars.

Due to the company’s expertise in this field, the Communications Manager Martijn Boelhouwer provides an insight into the regular procedure of battery recycling at ARN Recycling.

Your company offers businesses to participate in the ARN Management Plan that supports businesses in complying with requirements that go hand in hand with battery management. What exactly is the substance of the ARN Management Plan?

ARN and Stibat (Dutch Battery Foundation) have implemented a system for the collection, logistics and processing of discarded batteries with a negative residual value. According to the Battery Management Decree (Bbb), car manufacturers and importers are required to take back both starter batteries and propulsion batteries from hybrid and electric cars, after use. By taking part in the collective system (for which they pay a management fee), they are transferring their obligations to ARN and Stibat. ARN takes care of the collection and processing of starter and propulsion batteries with a negative residual value (Lithium-ion batteries) and reports on this. ARN also reports on batteries with a positive residual value (lead-acid and NiMH batteries) accordingly.

In 2017, ARN presented a new method, using a battery box. According to your website, this packaging system is used to “safely transporting end-of-life batteries from electric cars”. How does this system work?

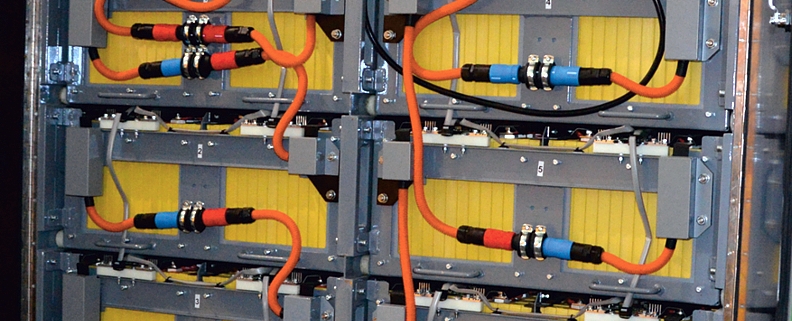

ARN has invested in order to enable collectors to safely transport batteries not safe for transport (in official terms: ADR, category 9, damaged or defective batteries liable to rapidly disassemble, dangerously react, produce a flame or a dangerous evolution of heat). Special battery boxes have been procured for the transport of non-transport safe batteries.

What is the major challenge when transporting end-of-life batteries from electric cars?

Safety in dismantling is a main issue. Safety is also essential in the processing of end-of-life vehicles. A non-dismantled lithium-ion battery in a shredder can pose a risk to both people and machinery. To raise awareness of such risks at companies in the chain, ARN has made an information video in collaboration with a shredder and provides training to car dismantlers.

On your website, you mention that “waste batteries must be dismantled and processed responsibly” since they contain hazardous materials. Which key factors does a responsible dismantling and processing of batteries imply?

Lead-acid starter batteries contain hazardous materials, such as lead and sulphuric acid. If these substances are released, they pose a danger to people and the environment. Waste batteries must thus be dismantled and processed responsibly. The Battery Management Decree gives guidance on how to go about this.

Photo: wikimedia

(GR 22019, Page 37-Interview)