Intelligent Management Systems by ECOVE

Taiwan-based company ECOVE boosts “resource cycling efficiency” of Energy-from-Waste (EfW) plants by iO&M (intelligent operation and maintenance systems).

ECOVE adopts iO&M in Miaoli EfW Plant to improve “resource cycling efficiency”, which is significantly better than the average level of other plants and recognized by competent authorities (Photo: CTCI Corporation)

Once dubbed “garbage island” for its overflowing landfills and filthy streets, Taiwan now has Asia’s highest rate of recycling and is a role model for the region. As the leading company of the resource recycling industry in Taiwan, ECOVE has promoted the establishment of integrated intelligent monitoring and warning systems in Energy-from-Waste (EfW) plants and waste management. These systems will provide real-time integration of management information for immediate judgment and response on business operations to ensure stable operations of each plant and improve “resource cycling efficiency”. With the economic development, the problem of waste treatment and garbage disposal in Southeast Asian countries is becoming more and more serious.

Establish iO&M System to optimize efficiency

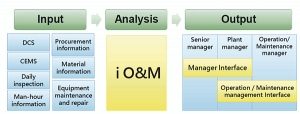

With the idea of industry 4.0, such as cyber-physical system, big data analysis and internet of things, ECOVE develops intelligent operation and maintenance (iO&M) systems which analyze various operational data and outputs to different levels. The output information can also feedback to different user-end functions to improve plants performance.

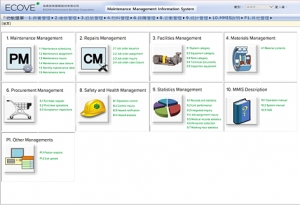

ECOVE has developed two core management systems: Maintenance Management Information System (MMIS) and Operation Results System (ORS), which became the preliminary structure of iO&M. The company also continues to optimize the system through accumulated data in the database.

MMIS implements preset maintenance plans through computer networks and cloud database. When there is something wrong with the equipment, it can be immediately integrated into information such as work orders, acceptance for maintenance, statistical analysis on equipment failure, work records and performance evaluation, maintain human resources, spare parts, and warehousing, to improve the team’s efficiency of equipment maintenance.

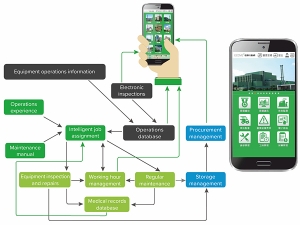

ORS continually records the operating information of each project to transmit, analyze, and feedback the information to various operating groups and the management. This accelerates decision-making and response time, and contributes to the goal of achieving remote management. The maintenance and operational results of each EfW plant will be reported to each operation group by ORS through procedures such as information input, storage, analysis, and output. The system also combines mobile devices that keep up with the times in order to optimize the performance of each equipment system, and achieve the purpose of comprehensive management.

Leading operational performance in the industry

ECOVE establishes MMIS that includes a database for maintenance, repairs, facilities, materials, procurement, and safety and sanitation (Source: CTCI Corporation)

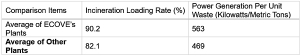

Through iO&M management, each plant has achieved outstanding operational performance. Taking ECOVE’s EfW plants, according to “2018 statistics of 24 EfW plants in Taiwan”, issued by Taiwan Environmental Protection Agency(EPA), ECOVE has imported iO&M system to its EfW plants and showed excellent performance in the following key operating indicators.

First of all, the “Availability Rate” and “Unscheduled Shutdown Hours” need to be mentioned. These are reliability indexes for maintaining stable operations for EfW plants. Managed by ECOVE with “iO&M”, the plants perform an average of availability rate 6.3 percent higher than others; the average unscheduled shutdown time is 182 hours lower than the shutdown time of other plants. The tables show that ECOVE improves operational efficiency with iO&M, which are significantly better than the average level of other plants. For example, ECOVE Miaoli EfW Plant and ECOVE Keelung EfW Plant have won first place in 2018 and 2019 in the EPA Annual Appraisal, indicating outstanding performance that is recognized by competent authorities.

Oversea iO&M performance

ECOVE adopts iO&M in an oversea country too. Taking Macau EfW Plant, for instance, it has been operating up to 27 years so far. With the support of iO&M, ECOVE successfully extended the equipment’s service life of the plant, maintained stable operation, and improved the electricity generation efficiency. Upon ECOVE’s iO&M, electricity per waste is increased by 25 percent, which maximizes the efficiency of waste per ton, making it one of the successful cases in resource cycling.

“iO&M” utilizes mobile devices to enable managers to stay updated of the status of plant operations and help them achieve precise and

in-time management (Source: CTCI Corporation)

Recycling rate or resource recycling technologies – Taiwan’s technologies are among the best in the world. Furthermore, Taiwan’s waste treatment experiences can be a successful example for other countries. EfW plants have been in operation in Taiwan for more than 27 years. With this extensive experience, the routine works of EfW plants have been successfully implemented based on the concept of “iO&M”. With considerations given to the overall performance and equipment life cycle, this system meets the needs of long-term operation management and helps the plant to achieve intelligent management.

ECOVE, Taiwan’s largest environmental resource management company, will continue to expand and develop a network of intelligent operations. The company will also improve the operations of EfW plants to effectively and efficiently control the issues of municipal wastes.

Source: ECOVE

____________

ECOVE (TPEx: 6803) – an affiliate of CTCI, a global engineering services provider – is an environmental services provider specializing in Energy-from-Waste (EfW), solar power, waste management, and resource recycling, such as wastewater, solvent, and PET recycling. Founded during Taiwan’s waste crisis in 1994, it quickly became a leader in effective waste management and resource recovery. With its main focus on recovering more value from otherwise wasted resources, it has continuously increased efficiency across our EfW, solar power, and recycling plants. Public and private entities in Taiwan, Macau, mainland China, Southeast Asia, India and the United States have trusted ECOVE regarding environmental services in operations and maintenance, consulting, and investment and development.

____________

2018 statistics of 24 EfW plants in Taiwan

(Availability Rate & Unscheduled Shutdown Hours) Source: https://swims.epa.gov.tw/Statistics/Statistics_Year.aspx, issued by EPA, Taiwan

2018 statistics of 24 EfW plants in Taiwan

(Incineration Loading Rate & Power Generation Per Unit Waste) Source: https://swims.epa.gov.tw/Statistics/Statistics_Year.aspx, issued by EPA, Taiwan

Macau EfW Plant greatly increases electricity generation efficiency under the operation of ECOVE (Source: CTCI Corporation)

(GR 32019, Page 38, Photo: CTCI Corporation)