Eldan Super Chopper Reduces the Power Consumed Tremendously

Recent advances in the market of electrical components have made it possible for Eldan to develop a frequency drive for the new versions of the Eldan Super Chopper, with a significantly lower power consumption and at a remarkably lower expense than previous models.

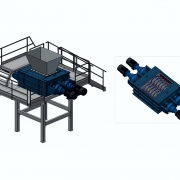

For more than 20 years the Eldan Super Chopper has been the first choice for a heavy-duty pre-chopper in any recycling process. It can be used for pre-chopping of most materials e.g. tires without prior de-beading, cables and electronic and electrical waste, refrigerators, aluminum, municipal solid waste (i.e. MSW), wind turbine wings (cut-off), plastics and industrial waste. One part from the traditional hydraulic version, the Eldan Super Chopper is now also available in frequency drive. The new Eldan Super Chopper Frequency Drive has the same strength, capacity and function as the hydraulic version, but will also reduce the power consumed tremendously.

Lower energy consumption

“We launched the Eldan Super Chopper with frequency drive during the first quarter of 2018, and it has been very well received by customers. We already have several new machines in operation and additional ones to be installed soon. The customers are located all of the world e.g. in Russia, Northern Africa, Ecuador and southern Europe,” says Jan Kjær, Manager R&D at Eldan. “The energy consumption of the Eldan Super Chopper with frequency drive is even lower than we first predicted. The start-up power is less than 10 percent of nominal KW, and the average power consumption is reduced by up to 50-60 percent.”

Further development

The Super Chopper SC 1412-II and the slightly bigger version SC 2118-II are the results of further development of the single shaft shredders. The Super Chopper has been developed to handle larger volumes, but also to be able to shred bigger size input material. Eldan Recycling A/S has sold the Twin Shaft Super Chopper for many different purposes so far; e.g. tire shredding in Spain / cable and aluminum shredding in the UK, as well as copper wire in Texas, USA. The company has just prepared orders for two new units, one for Spain and one for the US market. The previous Super Choppers were hydraulically driven. But as Eldan has been facing demands for more climate-friendly machines, the company has developed the frequency drive units. This allows for great savings in terms of power consumption and thus cut production costs considerably. This makes the new Super Chopper environment-friendly and cuts CO2 emissions. Apart from the above improvements, this new version of the Super Chopper works just like the traditional hydraulic version. Full power forward, reversing when overloaded using less power (KW) and rotational speed (RPM).

(GR12020, Page 56 / Advertorial, Photo: Eldan Recycling A/S)