Forrec: The Young History of an Internationally Acknowledged Company

Forrec – a growing and dynamic company that concentrates on the research, design and construction of a range of machinery for various fields of application – will exhibit at this year’s IFAT in Munich. GLOBAL RECYCLING Magazine wanted to get to know the Italian-based company and discussed several topics with Marco Zoccarato, the company’s CEO.

The quick internationalization of your company has given Forrec both national and international acclaim. Nowadays, Forrec has established collaborations with partners worldwide. But how would you describe the company’s first steps?

Forrec was established in 2007. With the collaboration of its partners, the company can resort to twenty years of experience in designing and selling waste treatment plants.

The company has been established in Resana (Treviso) and after the first steps have been taken Forrec received positive feedback from not only renowned but also from new interested parties. In just a short time, the company acquired a pool of customers that appreciated the flexibility and attention given to each project. Only four years later, the company needed to find more space due to the exponential growth in production and its internal staff. In December 2011, Forrec moved to its new headquarters in Santa Giustina in Colle (Padua) to initial premises of about 3,500 square meters, which subsequently saw the addition of a warehouse of about 2,500 square meters, entirely used for spare parts.

The company, which had more than 90 employees at the end of 2019, runs a branch in Serbia. The country is an important partner that oversees parts of the production, i.e. heavy metal structural work. About 50 employees are working for the branch in Serbia. All of them are involved in developing projects which are researched and produced in the Italian headquarters. The development of the sales network and the quick internationalization process have given the company both national and international acclaim. Shortly, collaborations have been established with partners worldwide, while important goals have been achieved. Nowadays, the company has sales offices in Brazil, North America, Thailand, Russia, Turkey, Vietnam, Dubai, Morocco, France, The Netherlands and the UK.

Forrec designs and realizes industrial shredders, grinders and granulators. Thus, the company offers solutions for various fields of application. Which are your primary utilization fields?

In general, municipal and industrial waste is our field of application, since the beginning Forrec has given a lot of attention to all the different kinds of products to reintegrate them in the market. Nowadays, the market is always looking for cost-effective solutions. Sure, we are environmentally friendly, but – frankly speaking – how much can we earn from recycling? The trends are different, for a certain period, we have mainly dealt with multi-crushers, double shaft machines, which can prepare the municipal waste before transforming it in RDF (Residual Derived Fuel), but also a powerful machine, that can process bulky and industrial waste in enormous quantities.

E-waste is always a primary application field for Forrec. The company’s WEEE recycling plants and refrigerators recycling plants (last year, Forrec installed the two biggest ones worldwide) show what our technology can do. Moreover, an enormous number of other components gravitate in the orbit of WEEE: cables, electric motors and metal scraps. But Forrec has developed its technology for the treatment of these components.

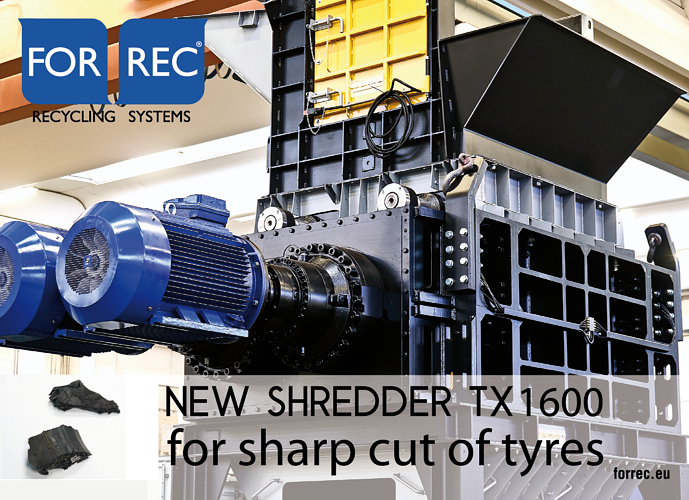

Moreover, tire treatment is also part of our daily work since the extra-European market is facing new directives to deal with this dangerous waste. However, Forrec has developed a complete system to get the crumb rubber (0-4 mm) from the process. This product is then integrated into the market with technical items and asphalt bitumen. Forrec has also designed a brand-new machine to obtain a “sharp-cut” 50×80 mm shredded tires, perfect as TDF (tire-derived fuel) for cement factories.

Your company offers a range of reliable, flexible, and manageable products such as shearing machines, crushers, or hammer mills. Can these products only be used as single machines, or can they be used in line with other equipment too?

All our machines are designed to be used as single machines but can be integrated into complete systems as well. Forrec has always produced turn-key installations tailor-made for its customers.

Your customers can visit you at this year’s IFAT in Munich. From the range of products your company offers: Which machinery are you going to present?

The visitors are going to find us in hall B6 at our stand 209/308. There we are going to present two machines:

- the FR multi-crusher, a machine dealing with MSW, bulky waste, as primary shredder with special characteristics

- the TQ four shafts shredder, an extremely reliable machine that is suitable for a large range of products.

(GR12020, Page 16, Photo: Forrec S.r.l.)