The Fibersort Project

In March this year, the partners of the European Fibersort project reported that their machine is ready to start “valorizing global textile waste”. According to the information, this technology can automatically sort large volumes of garments and finished products by fiber composition.

The accelerating consumption and disposal practices in fashion cause textiles entering the market to reach their end-of-use rapidly. In North-West Europe alone, around 4.7 million tons of post-consumer textile waste is generated every year, a small portion of the global mountain of textile waste. On average, only 30 percent of these textiles are collected separately – the rest is lost within the household waste. “In the best-case scenario, these textiles are sold in the second-hand market both locally and internationally”, Circle Economy, the leading partner of the Fibersort project, informed. “The remaining textiles are considered non-rewearable textiles due to their unsuitability for the second-hand market or the market saturation that second-hand clothing is currently facing. Almost all of these textiles are currently being downcycled, incinerated or landfilled. Nevertheless, 24 percent of the textiles collected have the potential to be recycled into new textiles, but currently are not.” These textiles would represent 486,000 tons per year.

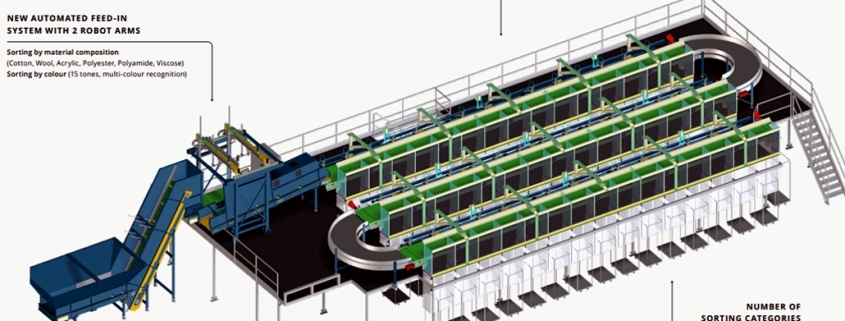

Automated sorting technologies could enable the industry to turn non-rewearable textiles that currently have no other destination than downcycling, landfill or incineration into valuable feedstock for textile-to-textile recycling. One of these technologies is the Fibersort, a Near Infrared (NIR) based technology able to categorize textiles in 45 different fractions based on their fiber composition and color. “Over the past years, the technology has been optimized, tested and validated to prepare it for commercialization”, a press release said. The Fibersort were now able to sort about 900 kilograms of post-consumer textiles per hour.

“Fibersorted materials are ready for the market”

According to the Fibersort partners, the success of the technology is highly dependent on the end-markets that help to transform textile waste into new resources. During the project, they have worked with 360 industry stakeholders – that have participated in working group and producer network – to better understand these end-markets, assess the potential of the sorted materials and validate the business case of automated sorting as a key enabler of textile-to-textile recycling. “Results from these activities are available through project publications and Fibersorted materials are now commercially available for other organizations to test their potential for textile-to-textile recycling”.

Challenges remain ahead

“There are clear opportunities to successfully integrate automated sorting technologies and recycled post-consumer textiles across the value chain”, the partners are convinced. However, several challenges would remain to ensure the long-term implementation of these technologies concerning financial and technical feasibility as well as the opportunities to scale. Collectors, sorters, recyclers, manufacturers, brands and policymakers would have both opportunities and responsibilities to address these challenges. Although the Fibersort project has reached its ending date in March, “the partners in the Fibersort consortium expect to continue working towards this circular ambition, as well as encouraging others to join the journey”.

Barriers and opportunities

In the final report of the Fibersort project, the key barriers and critical success factors for an effective market uptake of post-consumer recycled textiles and automated sorting technologies are described.

The biggest hurdles are:

- Making “recycled” the new norm: exploring socio-cultural barriers. Culture – whether organizational, national or community-driven – shapes individual perceptions that impact on consumer and industry practices. The lack of urgency in appropriately handling the growing mountain of textile waste as well as the negative perception of recycled content in textiles must be addressed.

- Creating new materials from post-consumer textiles: overcoming physical barriers. Textile-to-textile recyclers are in need of reliable feedstock for their processes. While sorting by fiber composition and color through automated near-infrared technology enables these materials to be sorted, consistency, quality and chemical safety of the post-consumer textiles are essential.

- Making recycling a sound business choice: reducing economic barriers. To secure a thriving end-of-use value chain for textiles, it is crucial to be aware of market demands, costing and pricing of sorted post-consumer textiles. Accelerating the development and implementation of recycling technologies as well as ensuring price parity with virgin alternatives will determine its financial feasibility.

The opportunities are:

- Develop a thriving collection and sorting industry by ensuring there is a business case to collect and sort the growing mountain of post-consumer non-rewearable textiles.

- Create a market pull for recycled content by incorporating recycled content in new textile products developed.

- Assess and communicate the urgency of action within organizations as well as to citizens and consumers.

- Maximize the quality and consistency of post-consumer inputs by providing accurate feedstock for the relevant recycling technologies.

- Safeguard the value of sorted materials as recycled content by testing these materials for diverse applications and ensuring product safety.

- Accelerate the implementation of recycling technologies by investing in their development and scaling.

- Ensure the price parity of recycled with virgin by lowering processing costs of post-consumer textiles and recognizing the true cost of virgin alternatives.

www.circle-economy.com/programmes/textiles/fibersort

www.valvan.com/products/equipment-for-used-clothing-wipers/sorting-equipment/fibersort/

(GR22020, Page 29, Source: Fibersort)