BRAIN by PICVISA: Production Process Consultancy through Deep Learning Technology

After the first three, we are now in what is theoretically known as the fourth industrial revolution. This new era builds on the changes generated by the Digital Revolution (the previous period) and is marked by the convergence of digital, physical and biological technologies.

The advances made in Artificial Intelligence have taken this technology almost from fiction to a consolidated practice in a matter of a few years. Industries and production processes of all kinds have been completely transformed or are on the way to doing so as a result of its application, while new business models have emerged.

Driving automation

The servitization of the industry is already a fact. From worrying only about manufacturing their product and leaving the associated services to third parties, more and more manufacturers are taking the lead and offering them directly. In this new era where everything can be connected, customers prefer complete solutions to stand-alone products. In this context, BRAIN by PICVISA was developed; a consultancy, analysis and feasibility studies service aimed at those industries interested in promoting the automation of their plants. By applying Vision and Artificial Intelligence technologies, data from the production processes are collected. Based on these data, the viability of the project is assessed not only from a technical point of view but also from the Return on Investment (ROI).

Based on the gathered information, businesses can act to improve certain processes, maximize their efficiency and, ultimately, become more competitive.

Artificial Intelligence for all industries

BRAIN by PICVISA is a service for any industry requiring detailed object and material recognition and analysis solutions (packaging, recycling, textile, pharmaceutical …).

With the AI-based flow analyzer ECOFLOW, valuable process information is monitored and captured for decision-making. All this data (trends, alarms, maintenance warnings, consumption habits …) together with other data generated by the rest of the ECOPACK, ECOGLASS, ECOPICK equipment are processed, converted into information and presented in the form of a customized proposal that goes beyond the integration of a machine.

Customers who choose BRAIN, receive a complete business improvement proposal, based on the opportunities offered by Artificial Intelligence, to convert a waste plant into a 4.0 plant in an optimal way.

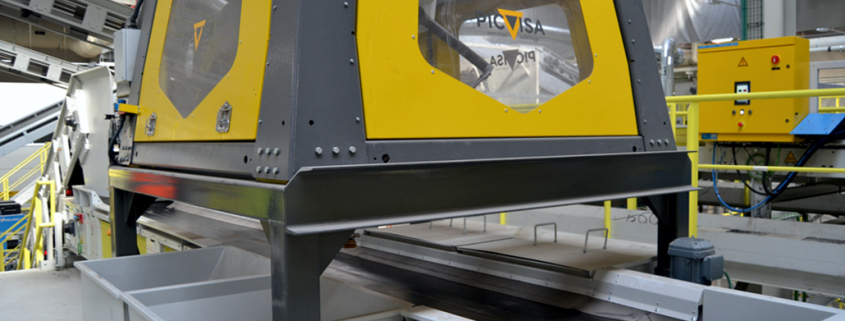

Full-scale tests at the Test Centre

To develop this service, PICVISA has a Test Centre located in Barcelona where the company can conduct performance tests, material studies and the mentioned feasibility tests. With 800 m2, the Test Centre is a laboratory for industrial-scale waste recovery and recycling tests where the performance and production of PICVISA equipment can be confirmed for a wide range of waste. The plant is fully automated and incorporates state-of-the-art machine vision and sensor technology with its equipment: an ECOPICK robot unit, an ECOPACK 2000DT, an ECOGLASS 1000 and an ECOGLASS 1500.

PICVISA has been helping recycling plants to increase their productivity with Machine Vision and Artificial Intelligence solutions for over 20 years. BRAIN by PICVISA is the result of the knowledge and experience built by the company over the last two decades.

(Published in GLOBAL RECYCLING Magazine 1/2021, Page 19, Advertorial, Photo: PICVISA)