SABIC to Launch Circular Polycarbonate

SABIC, a global leader in the chemical industry, has announced the launch of its certified circular polycarbonate (PC) resin and blends.

As reported by the company, this material made from the upcycling of post-consumer mixed plastic is a first in the industry. An internal SABIC LCA study had shown that the certified circular polycarbonate would offer a potential carbon footprint reduction of up to 23 percent in comparison to its incumbent. Part of the multinational company’s TRUCIRCLE portfolio of circular solutions, the certified circular polycarbonate is produced through the advanced recycling of post-consumer mixed plastic that could otherwise be destined for incineration or landfill. Through pyrolysis, difficult-to-recycle used plastic is broken down into pyrolysis oil. “This is then used as a feedstock to create certified circular building blocks for high-performance plastics with the same properties as the virgin material – in this case, polycarbonate,” the chemical manufacturer said.

Polycarbonate – more specifically LEXAN resin – forms part of SABIC’s ETP portfolio including PC blends such as CYCOLOY and XENOY resins. “Customers across industries – such as E&E, Automotive, Healthcare, B&C and Consumer Goods – may use the certified circular polycarbonate under identical process conditions to those used for its incumbent.” The polycarbonate is certified by an independent third party under the International Sustainability and Carbon Certification (ISCC PLUS) scheme using a standardized mass balance approach. That provides a method of asserting the recycled material content along with predefined and transparent rules. In addition, the widely recognized ISCC PLUS accreditation provides traceability along SABIC’s physical-linked supply chain, from the feedstock to the final product, requiring a chain of custody based on the mass balance system.

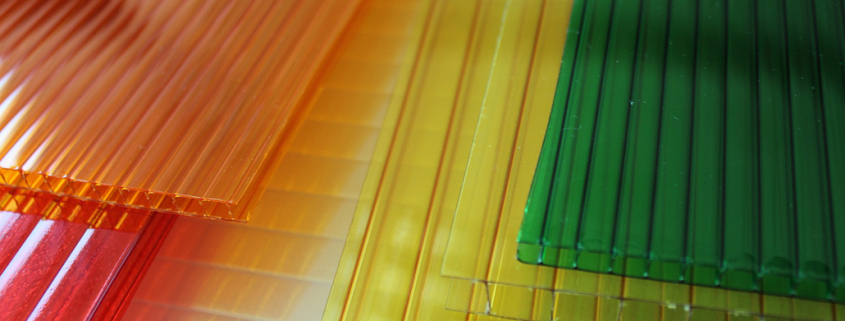

(Published in GLOBAL RECYCLING Magazine 3/2021, Page 26, Photo: Marlon Falcon Hernandez / pixabay.com)