Brazil: New Sorting Facility Starts in 2022

German-based plant engineering firm Stadler has signed an agreement with Orizon Valorização de Resíduos for the construction of the largest mechanical sorting plant in Brazil.

Upon completion, the facility is expected to process 500,000 tons of solid waste per year in the country where the potential for recycling is growing. According to Stadler, the contractually

agreed plant construction represents a technological breakthrough in the operations of the Jaboatão dos Guararapes Ecopark in Pernambuco (northeast Brazil), which would allow greater reuse of recyclable waste. In 2020, the plant received 1.5 million tons, equivalent to the waste generated by 3.7 million Brazilians. “The agreement also sets an example of the management and use of technology for the sector,” Alexandre Citvaras, director of Business Development at Orizon Valorização de Resíduos, is cited. As stated by the engineering firm, the plant in Pernambuco will be the largest mechanical sorting plant ever built in the Brazilian market. The German company has designed and implemented the entire project with two overarching objectives: to modernize and strengthen Orizon’s plant for the sorting process and select the recoverable products with the highest value to serve increasingly demanding domestic and international markets.

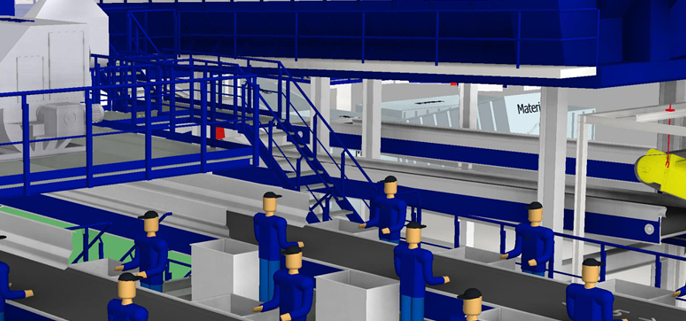

“The biggest challenge had been to design a sorting process with proven technology that increases the efficiency of the waste treatment at the Jaboatão dos Guararapes Ecopark,” Alexandre Citvaras gave account according to the information. “With this machinery, we will achieve a sorting efficiency ranging from 75 percent to 85 percent of the economically viable recyclable material. It is a breakthrough in our operations, which have gained in productivity and will play a key environmental role by returning materials to the production chain, helping to move us towards a true circular economy.” Contract partner Stadler has been chosen because Orizon Valorização de Resíduos believes that the plant manufacturer realizes “machinery with the quality and robustness required to process the type of solid waste that the ecopark receives, and which, at the same time, keeps the quality control with manual sorting”. It is intended that at the new sorting plant, 150 people will be employed to “carry out this work in the project, which will start its operation in 2022. This is why we needed a project that combines the two models,” the Orizon manager depicted the requirements.

A very ambitious project for the Brazilian market

Henrique Filgueiras, Stadler’s sales representative in Brazil, explained that the said agreement is “extremely important”. It would strengthen further the plant manufacturer’s relationship with a customer “that we have known and worked with for more than seven years – a company that has a lot of potential here in Brazil. In addition, it is a plant with a high capacity for processing MSW – the highest in Latin America – and a project on this scale strengthens our reputation as specialists in this type of plant in Brazil. The agreement gives us the opportunity to do a good job in another project and gain even more experience in Brazil.”

As reported, this plant has been designed to process a large volume of material with the initial separation of the coarse and heavy fraction through mechanical sorting and the final separation of the fines by hand. In addition, the plant layout already envisages the possibility of extending the line to increase its capacity, as well as increasing the automation of its processes.

Orizon Valorização de Resíduos operates five ecoparks in Brazil. Its waste management and processing facilities receive approximately 4.6 million tons of waste per year, serving approximately 20 million people and more than 500 business customers. Because of the new plant’s efficiency and prominence, the project will be rerun in the future in the rest of the company’s facilities throughout the country.

Specific peculiarities of the market

The Brazilian market has specific characteristics; a detailed analysis of the individual cases is necessary before presenting a solution to the customers. According to André Galuppo, supervisor at Stadler for Latin American projects, “Stadler always seeks to develop products, methodologies and ideas that are specific to the Brazilian reality. We do not ‘copy and paste’ projects from Europe. The objective is to develop projects, studies and work focused on Brazilian waste and business models. This technical and intellectual development will be used in Brazil and for Brazil, benefiting the entire market.”

“We have been investing in Stadler do Brasil Ltda. for more than eight years to provide local support that can be relied on,” Stadler’s Director of Latin American Operations, Sergio Manchado Atienza, was quoted. The goal was to help develop the market in a country “as important as Brazil, and with many resources necessary for the evolution of the circular economy. We are very proud of the work and development of our Brazilian subsidiary.”

(Published in GLOBAL RECYCLING Magazine 3/2021, Page 32, Photo: Stadler)