Volkswagen Group Establishes European Firm for its Battery Business

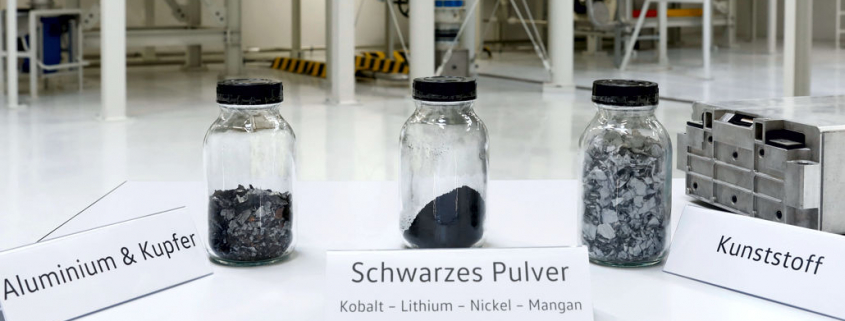

The company’s scope will include new business models – and partnerships – based around reusing discarded car batteries and recycling the valuable raw materials they contain.

The new European company (Société Européenne) will have to consolidate activities along the value chain for batteries – from processing raw materials to developing a unified Volkswagen battery to managing the European gigafactories, the car manufacturer announced last year. Volkswagen Group would thus create “efficient and future-proof structures for the rapidly growing battery business”. As part of its NEW AUTO strategy, the concern wanted to become the world’s leading manufacturer of electric vehicles.

Volkswagen is planning to establish six gigafactories in Europe to cover the growing demand for battery cells within the Group. Battery cell production in the Salzgitter facility is set to start in 2025. The gigafactory in Lower Saxony would produce unified battery cells for the Volkswagen Group’s volume segment. In its initial phase, the factory would have an annual capacity of 20-gigawatt hours; later on, this is planned to double to 40-gigawatt hours. Based on the current planning round, the Volkswagen Group is investing in developing battery cell production in Salzgitter. All in all, two billion Euro has been earmarked for the construction and operation of the Salzgitter gigafactory up to the start of production.

The site in Salzgitter, Lower Saxony, will bring together development, planning and production control under one roof. Thus, it will become the Volkswagen Group’s battery center. “There are plans to build additional gigafactories at sites in Spain and Eastern Europe. The exact locations for gigafactories 3 and 4 are due to be decided in the first half of 2022. Volkswagen intends to open two more battery cell factories in Europe by 2030.”

Optimized battery cell manufacture

Parallel to the development of these five gigafactories by the newly formed European company, the Swedish company Northvolt AB – in which Volkswagen has a stake of around 20 percent – will be building another factory in Skellefteå in northern Sweden. That will produce battery cells for the premium automotive segment starting in 2023. Northvolt already has an established partnership with the Volkswagen Group for premium battery cells.

Volkswagen is forging ahead with the industrialization of battery technology at all levels of the value chain, the Group underlined. The company has agreed to two strategic partnerships with Umicore and 24M and a long-term supply agreement with Vulcan Energy Resources. “The goal of the partnerships is to aid the manufacture and procurement of primary materials as well as to optimize battery cell manufacture at the planned gigafactories,” Volkswagen underlined. Those alliances were “designed to build know-how in battery technology and optimize cost management”.

Over the next five years, the Group intends to invest about 52 billion Euro in the development and production of new electric vehicles. “The NEW AUTO strategy also covers the development of the new business field batteries, charging and energy”. In addition, the manufacturer wants to create dedicated technology platforms that enable cross-brand synergies.

(Published in GLOBAL RECYCLING Magazine 1/2022, Page 18, Photo: Volkswagen AG)