Additives for Mechanically Recycled Plastics

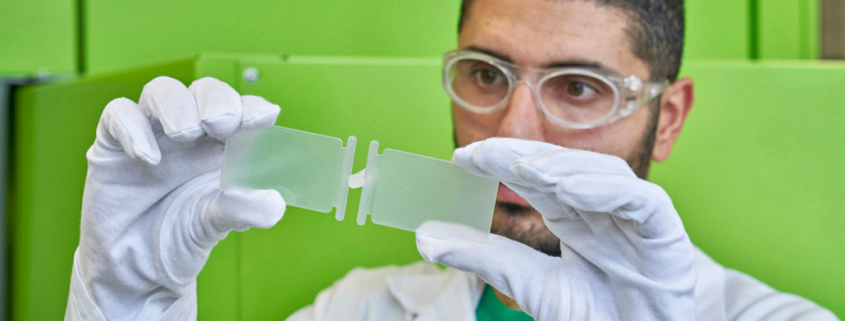

BASF has launched IrgaCycle, a new range of additive solutions to address the imminent needs in plastics recycling.

The plastics industry is seeking ways to incorporate higher content of recycled polymeric material in all major applications to meet sustainability goals while facing growing consumer concerns and stricter regulatory requirements to reduce plastic waste. According to the multinational chemical company, a major challenge was to mitigate quality deficiencies of polymers arising from thermal and mechanical stress during the recycling process. “Recycled plastics often contain impurities and polymer contaminants that accelerate polymer degradation, which change the material properties. Consequently, recyclers and plastic converters are facing quality and performance issues while processing recycled polymeric material,” BASF stated. “Formulated additive packages improving the properties of these recycled plastics can be a solution for this challenge.”

As pointed out, the company’s IrgaCycle range includes additives that can help increase the percentage of recycled content in several end-use applications such as packaging, automotive and mobility, building and construction. These products would address specific quality issues such as limited processability, poor long-term thermal stability and insufficient protection from outdoor weathering. “At launch, the product line includes a range of different additive formulations, with more to follow in the future.” The additives are ready to use and easy to apply in the recycling steps, BASF assured. “The granulated non-dusting product form ensures safe and easy dosage during converting or compounding of reclaimed material.” The IrgaCycle additive range is offered as part of the VALERAS portfolio.

(Published in GLOBAL RECYCLING Magazine 1/2022, Page 23, Photo: BASF)