Plastics: From Recycling to Upcycling

Researchers have developed a clean and cost-effective way to upcycle used plastic, transforming it into valuable nanomaterial and high-quality fuel, Australian RMIT University reported.

As stated, the new method from researchers at the university can produce high-value products from plastic – carbon nanotubes and clean liquid fuel – while simultaneously upcycling agricultural and organic waste. The two-step process would convert organic waste into a carbon-rich and high-value form of charcoal then uses this as a catalyst to upcycle the plastic. According to lead researcher Associate Professor Kalpit Shah, upcycling two massive waste streams through one circular economy approach could deliver significant financial and environmental benefits.

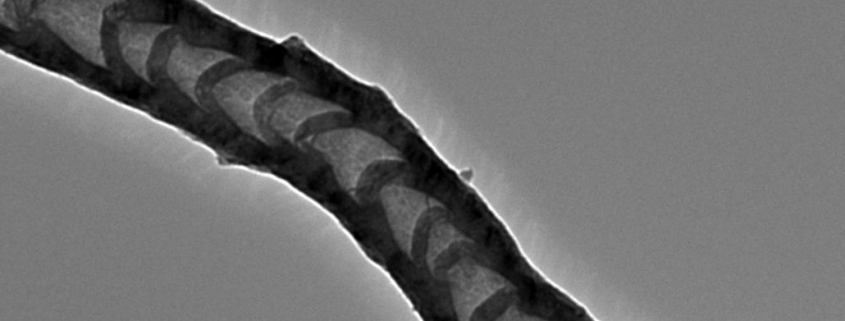

The new plastic upcycling approach would offer a sustainable alternative for the production of carbon nanotubes (CNTs), the Australian university gave account. “These hollow, cylindrical structures have exceptional electronic and mechanical properties, with applications across a broad range of sectors including hydrogen storage, composite materials, electronics, fuel cells and biomedical technologies.” The global market for CNTs was projected to reach 5.8 billion US-Dollar by 2027.

Turning old into new

The new method starts with converting agricultural or organic waste to biochar – a carbon-rich form of charcoal often used for improving soil health. The biochar is used to eliminate toxic contaminants – such as Polycyclic Aromatic Hydrocarbons (PAHs) – as the waste plastic is broken down into its components of gas and oil. “The process eliminates those contaminants and converts plastics into high-quality liquid fuel.”

At the same time, the carbon in the plastic is converted into carbon nanotubes, which coat the biochar. “These nanotubes can be exfoliated for use by various industries, or the nano-enhanced biochar can be used directly for environmental remediation and boosting agricultural soils.” According to the information, the study is the first to use low-cost and widely available biochar as a catalyst for making contaminant-free fuel and carbon nanomaterials from plastic. Shah, the Deputy Director (Academic) of the ARC Training Centre for Transformation of Australia’s Biosolids Resource at RMIT, said even though the study only investigated one type of plastic, the approach would apply to a range of plastic types. “We focused on polypropylene as this is widely used in the packaging industry,” he was cited. “While we need to do further research to test different plastics, as the quality of the fuel produced will vary, the method we’ve developed is generally suitable for upcycling any polymers – the base ingredients for all plastic.”

Hyper-efficient reactor

The experimental study, conducted at a lab-scale, could also be replicated in a new type of hyper-efficient reactor that has been developed and patented by RMIT, the press release said. The reactor is based on fluidized bed technology and would offer a significant improvement in heat and mass transfer to reduce overall capital and operating costs. The next steps for the upcycling research would involve detailed computer modeling to optimize the methodology, followed by pilot trials in the reactor.

The team from RMIT’s School of Engineering is keen to collaborate with plastic and waste industries to further the research and investigate other potential applications of the upcycling method.

An Australian Research Council DECRA Fellowship supported the research.

(Published in GLOBAL RECYCLING Magazine 1/2022, Page 53, Photo: RMIT University)