How PICVISA Uses Hyperspectral Vision for Textile’s Recycling

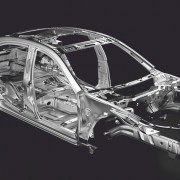

2025 is the key year. By then, all countries of the European Union will have to manage 100 percent of their textile waste, more than 16 million tons per year, as established by the European directives on textile recycling and waste management adopted in 2018. Technology takes a leading role in the automated classification of textile waste to make this challenge a reality. A technology based on the so-called hyperspectral vision, which allows a greater recovery of value through an automated separation of materials.

Automated sorting of textile waste

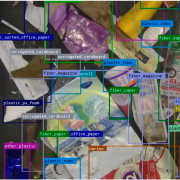

But what exactly is hyperspectral vision? This solution combines two different technologies. On the one hand, computer vision, which captures images of the real world, processes and analyzes them. On the other hand, infrared spectroscopy (NIR) allows to identify the composition of textile products, since each fabric has spectral characteristics that can be used for its classification. Textile fabrics are based on three types of fibers (natural, artificial and synthetic), with differentiated chemical and molecular structures that react differently to electromagnetic waves.

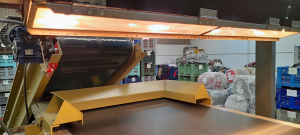

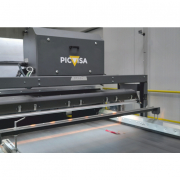

This technology, based on the classification of fibers by composition and color thanks to the use of infrared spectroscopy (NIR), is already widely used in automated sorting in other segments, such as PET recycling. In this sense, a key to the success of automated sorting technology will be the treatment of large volumes of textile waste. Something that Picvisa is already implementing, in this case, with an installation for Coleo Recycling in A Coruña, Galicia.

Artificial intelligence and artificial vision

In pursuit of the automation of the classification and separation of textile waste, Picvisa develops technological solutions based on artificial intelligence and artificial vision, such as the Ecosort Textile optical separator that, adding NIR technology and side blowing technology, allows to classify and automatically separate several types of textile waste, by composition (cotton, polyester, viscose and other fibers), color or shape.

On the other hand, Picvisa has developed a software that detects garments by their chemical composition and color and an automatic separation system in specific containers that allows classifying up to 24 different combinations of textile materials and colors simutaneously for the textile recycling company Coleo Recycling. Thanks to the technological solution implemented by Picvisa, Coleo Recycling classifies and traces some 5,000 tons of textile waste annually. However, the great challenge of textile recycling remains: the coexistence of different types of fiber in the same fabric. This coexistence makes post-consumer textile recycling, with tons of clothes of fibers mixed, more complicated than pre-consumer recycling, when it is easier to know the exact composition of a fabric and how to recycle it. The solution involves regulating the manufacture of garments through eco-design to limit the casuistry, and the development of processes, such as the manufacture of new fibers from recycled waste, which make the textile industry a circular economy.

More recycling, more sustainability

There is no doubt that the recycling of textile waste is a key element in reducing the huge carbon footprint of the industries that generate this type of waste. The reduction in environmental impact associated with using recycled fibers is impressive. In some projects, the energy savings of recycled versus virgin fiber can be 53 percent, while water savings can amount to 99 percent and chemical savings to 88 percent. Important percentages if one takes into account, for example, that the manufacture of one kilo of polyester fiber consumes 108 kilowatts/hour (kW/h) and 21 liters of water and emits 3.3 kilos of carbon dioxide.

To generate these percentages of energy efficiency it is necessary, however, to improve the recycling process of textile waste, with new selective collection systems, and, especially, with the improvement of the processes of selection and classification of this waste. Therefore, technological innovation is absolutely essential when it comes to optimizing these textile waste recycling processes. In this sense, textile recycling is emerging, without a doubt, as the first and fundamental step to get the second most polluting industry on the planet to begin its transition to sustainability. And this is where hyperspectral vision comes into play.

www.picvisa.com

www.youtube.com/watch?v=ahssWSgLHyw

(Published in GLOBAL RECYCLING Magazine 3/2022, Page 42, Photo: Picvisa)