SMS Group Supplies Process Technology for Green Steel Production Plant

German-based SMS group, has been selected to provide a broad range of technology and equipment for the H2 Green Steel project in Sweden.

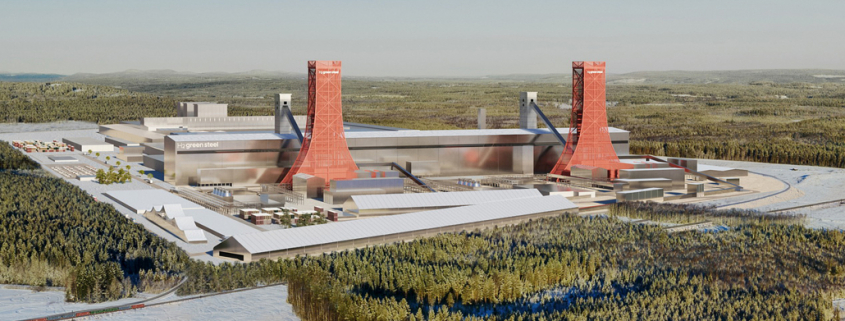

When completed, the plant will produce steel mostly from scrap collected for recycling, using green hydrogen instead of carbon. As reported, the H2 Green Steel site will be a almost 300 hectares greenfield project in Boden in the Swedish Norbotten region. The facility, called the “world’s first large-scale green steel production plant”, is expected to produce green steel by 2025, ramping up volumes in 2026.

The agreement will see SMS group, including Paul Wurth and its consortium partner Midrex, as suppliers of process equipment from ironmaking to finished steel products based on hydrogen and electricity from renewable sources. The partners will provide a MIDREX direct reduction plant, the Electric Arc Furnace (EAF) based melt shop, a CSP Nexus casting and hot rolling plant as well as an advanced cold rolling and processing complex for the production of a broad product mix including advanced high strength steel and automotive steel grades. “Leading car manufacturers have already signed agreements with H2 Green Steel for the supply of green, high-quality steel”, the German technology provider underlined. The total order volume for SMS group would exceed one billion Euro.

(Published in GLOBAL RECYCLING Magazine 1/2023, Page 20, Photo: SMS group)