PureCycle: Purification Plant Reaches Mechanical Completion

PureCycle Technologies, Inc. announced it reached mechanical completion of its first polypropylene purification plant in Ironton (Ohio, USA).

In May, the company informed that it received formal certification of mechanical completion from the site’s independent construction monitor. “The formal certification came three days after PureCycle submitted its documentation to the engineering company.” The evaluation is required to achieve the first key milestone in connection with PureCycle’s Ironton financings.

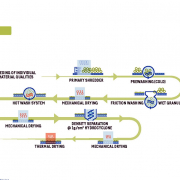

The Ironton facility was anticipated to commence in the second quarter of 2023, the company gave account. Once fully operational, it would be expected to produce 107 million pounds (more than 48 metric tons) of Ultra-Pure Recycled (UPR) resin annually, making high-quality recycled PP plastic more accessible at scale. PureCycle Technologies LLC., a subsidiary of PureCycle Technologies, Inc., holds a global license for the patented solvent-driven purification recycling technology, developed by The Procter & Gamble Company (P&G), “that is designed to transform polypropylene plastic waste (designated as No. 5 plastic) into a continuously renewable resource”. The purification process would remove color, odor, and other impurities from No. 5 plastic waste “resulting in an ultra-pure recycled (UPR) plastic that can be recycled and reused multiple times”.

(Published in GLOBAL RECYCLING Magazine 2/2023, Page 14, Photo: PureCycle)