A German Project: Lithium from Spent Electric Car Batteries

Led by ACCUREC Recycling GmbH, an internationally active company in battery recycling, various partners – specialty chemicals company Evonik, Oeko-Institut and the IME Process Metallurgy and Recycling Institute at RWTH Aachen – are working on a research project named “EarLi” to recover high-purity lithium from recycled batteries from electric vehicles (EV).

EarLi stands for extraction and purification of lithium hydroxide monohydrate from spent lithium-ion EV batteries for reuse in producing battery cells. As reported, the total project volume is over five million Euro and is funded by the project partners and the Federal Ministry for Economic Affairs and Climate Action (BMWK), Evonik informed in June this year. The research project is scheduled to run for three years.

While metals, such as nickel and cobalt, can already be recovered from batteries in high yields, this is not yet possible for lithium because the process is technically more demanding. As underlined by Dr. Ralph Marquardt, chief innovation officer at Evonik, researchers worldwide were looking for economically viable methods of recovering this valuable raw material for batteries in high quality. The company “wants to play its part in finding a solution that drives forward e-mobility with the lowest possible environmental impact.”

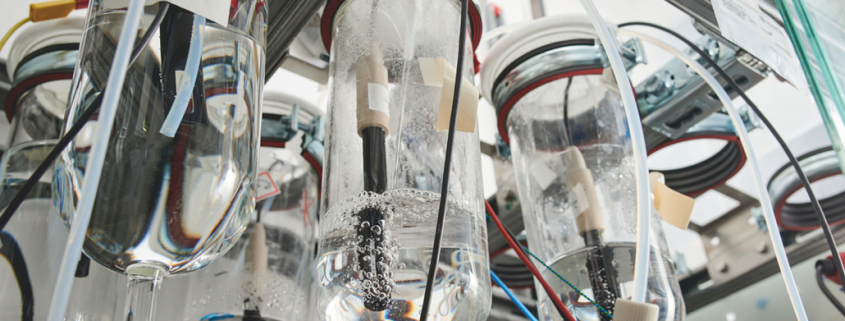

“To this end, an innovative process chain is to be set up on an industrial-type scale to convert the lithium from the black mass – a mixture of different active battery materials – into soluble compounds using a special thermochemical process and subsequently extract the lithium,” the information said. “The lithium will then be separated in an electrochemical process using a highly selective ceramic membrane and isolated as battery-grade lithium hydroxide monohydrate. The innovative membrane process should enable cost- and energy-efficient isolation of high-purity lithium hydroxide and thus close the lithium loop in the battery market. Evonik has been working for some years on the development of selective ceramic ion conductors for lithium ions and their application as separation membranes in an electrochemical process.”

accurec.de

corporate.evonik.com/en

oeko.de/en/

metallurgie.rwth-aachen.de

(Published in GLOBAL RECYCLING Magazine 3/2023, Page 42, Photo: Evonik)