Lithium-Ion Battery Recycling

The energy sector has turned to alternative vehicles due to reasons such as the increase in the number of vehicles in the world, rapidly decreasing oil resources, wars, and increasing pollution rates all over the world. Electric vehicles that developed for this purpose, have come to the fore in the production sector because their pollutant emissions are lower than conventional vehicles and they reduce dependence on oil.

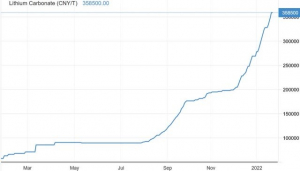

In addition, lithium-ion batteries are used everywhere from computer technology to drones and small household appliances. Although we use the definition of ‘green energy’ for these batteries, it is also true that they have a lifetime. The recycling of these batteries, which are used in almost every field, is an important problem. In addition, increasing lithium, cobalt, and nickel prices all over the world oblige us to recycle batteries.

Commercial lithium-ion batteries are produced in two types, cylindrical and square, depending on their use. However, regardless of the design, most lithium-ion batteries are produced by coating the cathodic active material, lithium cobalt oxide, on aluminum foil, which is used as the electrode plate, and carbon on copper foil. The battery material is made ready for consumption by being covered with a steel or aluminum body and then a plastic sheath. The components that make up the battery are iron, aluminum, copper, cobalt, lithium, and graphite. If the recycling of these metals becomes more widespread, the accessibility of electric vehicles will become widespread all over the world. In addition, the storage of waste batteries creates a great burden on companies and governments both in terms of economy and health. This burden also necessitates recycling.

Are Scrap Lithium-Ion Batteries Valuable?

Li-ion batteries end their life and are scrapped due to aging, overuse and overcharging. When the effects of ambient temperature are added, their lifespan is shortened. Perhaps the only disadvantage of Li-ion batteries is that they age and wear out even if not used. As a result of faulty production, some batteries are scrapped. Lithium-ion batteries are also valuable as scrap.

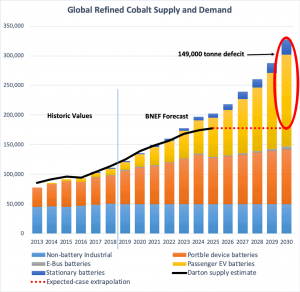

Because metals, especially lithium, cobalt and nickel used in their production, are very valuable and can be used in industry after recycling. There is constant demand from different branches of industry, especially for the cobalt, nickel and copper in these batteries. After recycling, these metals can be easily sold. For these reasons, li-ion batteries, which are separated as scrap, can be bought, and sold due to their material value.

What Are the Challenges of Li-Ion Battery Recycling?

Globally, we are already throwing away more than 600,000 tons of lithium batteries. Most of these are used in small electronic devices. As the world shifts to electric vehicles, the need for lithium batteries is predicted to increase tenfold by 2030. This is seen as an opportunity for battery recycling. However, when lithium-containing batteries (phone batteries, etc.) and lithium polymer batteries (model aircraft, car, control batteries) are physically damaged, they come into contact with air and start to burn. This situation requires very well-designed recycling systems. The cost of these machines, which are produced considering the safety of both the facility and the employees, is relatively higher than other recycling facilities. In addition, the structure of these batteries makes recycling difficult.

In order to prevent fires that may occur during accidents, especially in electric vehicle batteries, even opening the battery boxes requires trained personnel, attention, and special skills. In addition, the use of constantly changing materials for the development of batteries makes recycling difficult. Again, even if recycling efficiency is achieved in other mines by pyrometallurgical method, this is not possible in lithium. The cost of this method is also very high.

Is Lithium-Ion battery recycling profitable?

Li-ion batteries in all devices, small or large, are valuable and can be recycled. They also need to be transformed in terms of environmental health. Of course, this recycling process is not very easy. It requires special crushers and chemical systems. Until a few years ago, almost all collected lithium-ion batteries were sold to large refineries. Refineries made the biggest profits in this system, and the situation was not very attractive for collectors. In recent years, the efficiency of recycling has increased rapidly with the research carried out by both private companies and universities. In addition, a transformation revolution is taking place both in small vehicles such as bicycles and motorcycles, and in the electric vehicle industry. In this case, very large amounts of battery waste will occur in the very near future. These batteries are produced from small appliances or smartphones to many battery cells and from metals, whose value is increasing day by day, such as lithium, cobalt, nickel, copper, manganese in large quantities. Adding the increase in metal prices to such a large increase in the amount of scrap, li-ion battery recycling investment has become very attractive for many investors.

With the introduction of electric vehicles, scrap batteries will also be a problem for states. Investment incentives are provided for battery recycling facilities in most developed countries. Proses Makina has accelerated its efforts to develop recycling systems for lithium-ion batteries with its recycling experience in the field of electronic waste and catalyst. It has completed its R&D studies and made an agreement with its customer in the USA to establish a pilot plant with the least environmental impact and high efficiency.

Source: PROSES MAKINA (Istanbul, June 12, 2022)