The Role of Robotics in Advancing Industrial Recycling for a Sustainable Future

An increasing number of companies across various industrial sectors are turning to automation to streamline production processes. This shift aims to leverage technological advancements for enhanced efficiency, boosted production, and improved product quality. Importantly, many industries are incorporating sustainability into their strategic goals, recognizing the need for greener practices for long-term viability. A key component of this shift is the integration of robotics in waste recycling.

Robotics, combined with artificial intelligence (AI) and computer vision, is revolutionizing waste management. These technologies enable rapid and accurate detection, capture, and sorting of waste materials. That precision enhances recycling processes and significantly reduces the ecological footprint of industrial activities. The new generation of robotics is designed to minimize the environmental impact of manufacturing, fostering a balance between economic growth, environmental care, and social welfare.

The impact of these advancements is noticeable in sectors such as food, fashion, chemicals, and energy. By integrating circular economy principles, these industries are becoming more sustainable, efficient, and resilient. The circular economy model transforms waste into valuable resources, reducing the residual environmental impact. That approach is crucial in addressing global biodiversity threats and mitigating pollution’s adverse effects on human health and well-being.

The impact of these advancements is noticeable in sectors such as food, fashion, chemicals, and energy. By integrating circular economy principles, these industries are becoming more sustainable, efficient, and resilient. The circular economy model transforms waste into valuable resources, reducing the residual environmental impact. That approach is crucial in addressing global biodiversity threats and mitigating pollution’s adverse effects on human health and well-being.

One stark example of the need for circularity is the textile industry. According to Eurostat, the European Union exported 32.1 million tons of waste to third countries in 2022, slightly less than the previous year. The textile sector is a major environmental offender, trailing only food, housing, and transport in impact. Textile consumption pressures water and land use, with the EU discarding five million tons of textiles annually – an average of 11.3 kg per person. Shockingly, only one percent of the world’s clothing material is recycled into new garments.

In Spain, approximately 900,000 tons of clothing are discarded each year, and 88 percent end up in landfills. The European Commission has recognized the urgency of this issue and launched the Circular Economy Action Plan, including the Strategy for Sustainable and Circular Textiles. This strategy aims to ensure that by 2030, all textile products in the EU market are durable, recyclable, and produced with respect for social and environmental rights. The strategy involves comprehensive measures to transform the entire lifecycle of textile products.

In Spain, approximately 900,000 tons of clothing are discarded each year, and 88 percent end up in landfills. The European Commission has recognized the urgency of this issue and launched the Circular Economy Action Plan, including the Strategy for Sustainable and Circular Textiles. This strategy aims to ensure that by 2030, all textile products in the EU market are durable, recyclable, and produced with respect for social and environmental rights. The strategy involves comprehensive measures to transform the entire lifecycle of textile products.

Robotics plays a pivotal role in transforming waste management across all sectors generating industrial waste, including electronics, metallurgy, glass, food, iron and steel, paper, and chemicals. Here is how robotics enhances waste management:

1. Automating Tasks: Robots perform dangerous, repetitive, or undesirable tasks for humans, improving workplace safety and efficiency.

2. Accurate Sorting: With advanced sensors and machine vision, robots identify and sort various waste types with high precision.

3. Resource Optimization: Robots detect valuable materials within waste streams, maximizing resource recovery and converting waste into new resources.

4. Data Capture: Robotics systems generate data to improve decision-making and strategy implementation. AI algorithms process this data to identify patterns and enhance recycling efficiency.

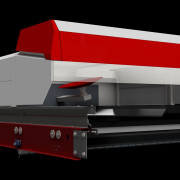

Industries aiming to improve waste management can find effective solutions with companies like PICVISA. By embracing automation, these industries can turn waste management challenges into opportunities, reducing environmental impact and promoting sustainability. Robotics offers a pathway to a more sustainable and efficient future in waste management, demonstrating that innovative approaches can lead to a better waste management paradigm.

(Published in GLOBAL RECYCLING Magazine 2/2024, Page 14 -Advertorial-, Photos: PICVISA)