Tanaka Precious Metal Group Collaborates with Jeplan

The two Japanese companies have decided to enter into a business partnership to reduce CO2 emissions and promote the recycling of organic materials in the precious metal recovery processes of Tanaka Precious Metal Technologies Co., Ltd.

Since its founding in 1885, Tanaka has been a leader in the precious metals industry, actively engaged in recycling these resources. “Among the process waste materials received from customers who request recycling, those containing organic materials (plastics) as main components with precious metals attached or adsorbed have traditionally been processed through incineration to remove the organic materials, with precious metals then recovered from the ash left behind,” the information said. “While this incineration process has addressed the removal of environmentally regulated substances, the reduction of CO2 generated during the combustion of organic materials has become a major challenge in realizing a decarbonized society.”

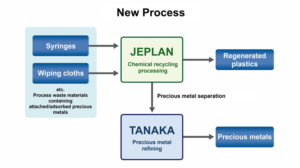

Jeplan has established a proprietary chemical recycling technology for polyethylene terephthalate (PET). To address the aforementioned CO2 emissions issue, Tanaka is considering using chemical recycling in the future, in addition to the conventional precious metal recovery process through incineration. “This initiative is being explored through a business partnership with Jeplan.” As reported, the materials targeted for chemical processing include plastics such as syringes and wiping cloths. CO2 emissions from the targeted precious metal recovery process are expected to be reduced to approximately ten percent of conventional levels. In addition, this process would enable not only precious metal recovery but also plastic regeneration.

tanaka-preciousmetals.com, jeplan.co.jp

(Published in GLOBAL RECYCLING Magazine 3/2025, Page 22)