New Sorting Plant in Mexico

Operadora de Ferrocarril y Manejo de Rellenos (OFMRS) has joined forces with German manufacturer Stadler Anlagenbau to develop a plant in the city of Cuautla (Morelos, Mexico) capable of managing comprehensive waste treatment for 16 municipalities in Morelos and a small part of Mexico City.

Mexico is one of the world’s ten largest producers of Municipal Solid Waste (MSW) on account of its vast size and large population. The country generates around 120,000 tons of waste a day, which adds up to 44 million tons a year. This situation has been further aggravated by an increase in waste – estimated at between 3.3 and 16.5 percent according to a study (www.gob.mx/cms/uploads/attachment/file/569684/Residuos_COVID.pdf ) conducted by the Instituto Nacional de Ecología y Cambio Climático de México – due to the country’s lockdown period, which has affected patterns in consumption and medical treatment. In this situation, the new sorting plants based on the automation of waste management take on even greater importance for their potential to improve the environmental situation in Mexico and boost the circular economy, the German plant constructor stated.

The new sorting plant inaugurated by OFMRS was a testament to this trend towards automation. According to Natalya Duarte, Sales Manager for Mexico at Stadler, this project was born of the vision shared by OFMRS and the manufacturer on waste management. “The aim was to recover different types of recyclable packaging and materials and re-distribute them back into various production chains, as many times as possible. This innovative business and management model makes such projects feasible, as well as making them more profitable due to the highly-efficient sorting process and high purity levels of the materials.” As reported, the plant can sort by type of polymer and color.

With facilities spanning 3,800 square meters and a maximum output of 640-700 tons/day, OFMRS sorts, classifies, compacts and commercializes municipal solid waste, recovering materials including cardboard, paper, carton packaging, plastic, glass, and ferrous and non-ferrous materials. Biogas is also recovered from organic waste and fed to two Guascorde power generators; the energy generated is supplied to two companies in the state of Mexico through the power supply network owned by state-owned power utility CFE.

Closed-loop system

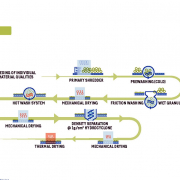

The plant’s automated closed-loop system comprises ten cutting-edge machines and thirty-five recirculating conveyor belts, Stadler informed. The process starts with the reception of the MSW, which undergoes several processing stages, including the removal of ‘non-recoverable’ waste. Then it is sorted into three groups: firstly, fine, metal and organic waste, which is sent to a reject container; secondly, flat or 2D waste (cardboard, paper, plastic wrap and carton packaging); and finally, bottled or 3D waste (PET, HDPE, PP, carton packaging and aluminum). The last two types of waste are forwarded to a manual sorting area. Finally, the conveyor belt feeds the materials into the compactor, and the final product is ready: recoverable waste bundles of cardboard, paper, plastic wrap, carton packaging, PET, HDPE, PP and aluminum.

To improve work practices, productivity, Occupational Health and Safety (OHS) and environmental protection, OFMRS has been operating to international ISO 9001 quality, ISO 45001 OHS and ISO 1400 environmental standards since mid-2020. According to Natalya Duarte, this is the “first project in Mexico that involves different parties in the recycling chain to protect the environment. It is also the first national project that sets out to industrialize and professionalize the process, seeking the highest efficiency and purity levels and adhering to the strictest quality standards, including ISO.” Stadler works closely with clients to optimize its integrated projects, the plant provider underlined. The company supplies clients with advice and support throughout the whole project and during the business model proposal. The after-sales service includes maintenance plans and spare parts stocking in greater volumes and for longer periods.

(Published in GLOBAL RECYCLING Magazine 1/2021, Page 49, Photo: Stadler)