The New Technology for Industrial Recycling of Municipal Waste Developed by Tehnix Achieves Circular Economy

The company Tehnix is the leading eco-industry in the Republic of Croatia and the European Union. The company has developed machines, equipment and technologies that are used for the best industrial recycling of municipal waste.

“Primary recycling fits completely into the industrial recycling system by delivering the recycled waste to the facility using recyclable values and returning it to the industry. The great experience, knowledge and development of new environmental technologies enabled us to gain a great interest in the global market for the application of MBO-Te new technology that achieves circular economy. This is the technological innovation of recycling in the sustainable management of municipal waste. With our achievements, we have introduced European experts who support the European Commission’s new communications with the goals of European policy for the circular economy and who want to significantly improve the existing waste management model in European countries, supporting projects that give the best results in the recycling process.

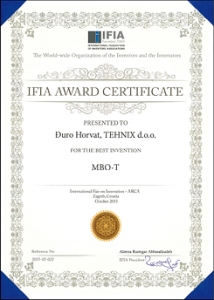

It is particularly noted, that waste management objects and facilities should be in line with the requirements of the best available techniques and technologies which should be applied in the design, construction and maintenance of recycling facilities. We have been working on the development of a new technology for more than 15 years for which we have received hundreds of recognitions and awards from all over the world. The European Commission supports those technologies that give the best recycling degree, such as the MBO-Te industrial recycling technology developed by Tehnix.

Technological advantages of construction of the recycling center for mixed and pre-sorted municipal waste management

Recycling facilities that are installed in recycling centers perform the complete recycling process. Complete municipal waste is sorted according to usable values and market needs. MO = mechanical treatment from which we obtain eight types of selected, baled raw materials – plastic, cardboard, paper, PET, MET, textile, glass and metal. All raw materials are completely clean, baled and sold on the global market for the production of new products in the industry. BO = biological treatment of organic waste and green waste. The process of bioreactor composting allows the cycle of production of eco compost in a period of only two months. Composting is carried out under fully controlled technological conditions without any negative impact on the environment and without water, soil and air pollution. Eco compost enriched with minerals and phosphate is used for agricultural purposes. TO = thermal treatment. The rest of the combustible waste, which cannot be recycled due to the size of the material and the structure, also dries and shreds, and automatically bales into the bale without human presence. The average energy value of dried RDF fuel in bales is four MW per ton. The total percentage of waste recycling at MBO-Te facility Tehnix is up to 100 percent. By such procedures we achieve the goals of sustainable development and circular economy and receive almost hundreds of acknowledgments from Europe and the worldwide confirmation of the benefits of our technological achievements in recycling. And constructed recycling facilities are working permanently.

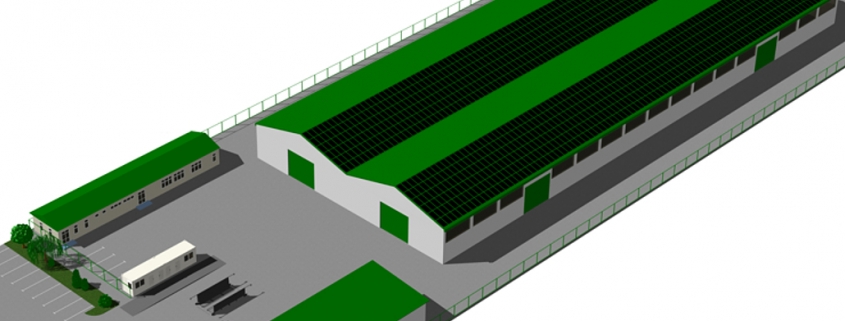

The construction of recycling centers lasts less than a year since the issuance of a construction permit. The small dimension of the project enables technological rationality and the flow of the recycling process. Solar panels are installed on the roof of the built-up facilities. By treating municipal waste, we achieve three general value systems: Economy – everything that enters is charged and everything that comes out is charged as well. Ecology of the recycling process allows the highest degree of recycling. A social advantage is recruiting people in the recycling process, especially those structures that are underrated in the labor market. Tehnix plants are very well adapted to local conditions. They are conceived to leak into small and medium-sized environments. They can be simply installed in old halls, thus improving the abandoned buildings. Basically, they are industrial plants with low energy consumption, which guarantees efficient sorting by employing local workers. The impact on the environment is extremely small and the working area in the manual sorting hall is ventilated and air-conditioned.

In large areas, industrial Tehnix sorting plants can be installed in two or more locations, thus reducing traffic within the site and guaranteeing the implementation of the proximity principle in the overall waste management system. Mechanical-biological recycling of pre-sorted or mixed municipal waste is a technological breakthrough developed by Tehnix. This technology is a major step forward in the economy of municipal waste management due to its technological flexibility, as it enables those technological innovations that achieve great impact and low costs in the recycling of the delivered municipal waste. “

GR 12018-Advertorial