FELEMAMG: Magnetic Separation

Since the establishment of Felemamg in 1970, a complete technique in the magnetism area has been developed, or more precisely, its application in the magnetic separation area has been evolved.

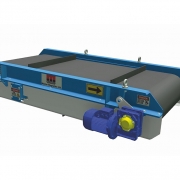

The magnetic separators, the “RS” and “RC” series, remove unwanted ferrous material from the non-magnetic ones in conveyor burdens. Usually, they are suspended over conveyor belts or vibrator conveyors.

Moreover, the company manufactures another separator, an eddy current separator type SFME, with an eccentric rotor, ideal for the recovery of aluminum, copper, brass, shredder plants, waste plants, glass and plastic recycling plants or wood recycling plants.

The separator element is a magnetic rotor provided with high remanence Neodymium permanent magnets. The created magnetic field with high frequency induces the Foucault currents in the conductor metallic pieces; these pieces create a magnetic field opposed to the rotor. The result is a repulsion force to the metallic elements, whereas the rest of the products carry on with their natural trajectory.

The basic version of the SFME non-ferrous eddy current separator is composed of:

- Eccentric magnetic rotor, with permanent magnets (Nd-Fe-B)

- Rotor outer shell, in fiberglass

- Conveyor belt with double longitudinal guided and double lateral

contention rejections - Motor and motor-gearbox for conveyor belt and rotor joined with

transmission belts and their protections - Lateral and frontal protection

- Adjustable divider wall in height and angle

- Electric equipment with rotor and belt speed regulation

- Rotor brake system

Optional, it can also be supplied with:

- Vibrating feeder

- Product output chutes

- Upper protections

(GR12020, Page 54/ Advertorial Photo: Felemamg)