Automatic Depollution of Flat Panel Displays

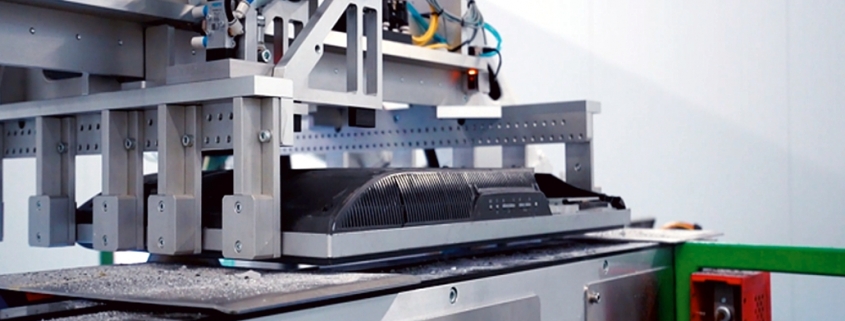

The USA-based company FPD Recycling has created a fully automated system, which simplifies the e-waste processing and increases the throughput.

The recycling of Flat Panel Displays (FPD) is dangerous, time-consuming and costly. Paudy O’Brien, CEO and founder of FPD Recycling, is convinced that he and his team of specialists have designed a solution to the problems that face e-waste recyclers the world over. To remove the hazardous components, they have created the system FPD Pro. According to the company, its technology uses artificial intelligence to enable substantially greater process speeds. The system is able to depollute 60 flat panel displays per hour – as opposed to a manual recycler, which – on average – can recycle just six per hour. As emphasized, the FPD Pro is a fully enclosed automated recycling technology that utilizes equipment for the automotive and pharmaceutical sectors to recycle FPDs. It meets the requirements of the EN 50625, 2-2 Treatment for CRT and FPDs 2015, EN 50625: 3-1 General depollution and EN 50625: 3-3 Depollution specification for CRTs and FPDs, the homepage informs. While tubes containing mercury are isolated, LC panels and diffuser sheets are separated and collected in bins. FDP shells can be further processed using standard recycling techniques.

“Effective dust and mercury capturing equipment ensures the recycler is not exposing their workforce to hazardous materials,” the company FPD Recycling assures. Along with the intrinsic design of the system, the technology would capture data such as weight, manufacturer, model and size during the recycling process, which can be used to build customized reports for the recycler. Additionally, there are more advantages provided by FPD Pro: The system realizes low operating costs and enables recovery rates of more than 80 percent.

(GR12020, Page 53, Photo: FPD Recycling)