Forrec and the Treatment of End-of-Life Tires

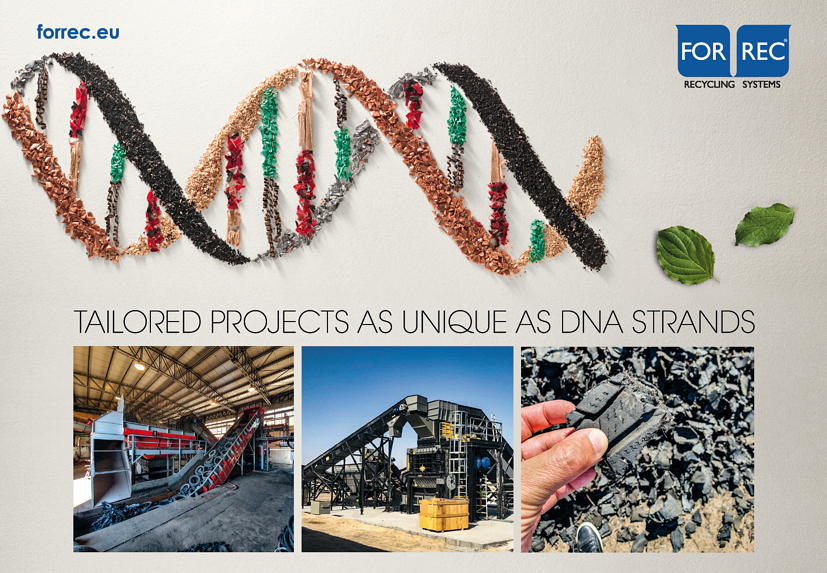

Forrec produces single machines and complete plants for the treatment of any type of municipal and industrial solid waste, and for almost 15 years has been present on the market with reliable and effective solutions.

Forrec‘s complete system allows obtaining a rubber granule with a size between 0.8 and 4 mm. With this recycled rubber from ELTs (end-of-life tires), innovative eco-sustainable products are made, which find application in very different sectors.

From products for the building industry, such as acoustic vibration insulation, playgrounds, soccer pitches, multi-purpose sports flooring and products for animal welfare. There is also the sector of roads and infrastructures, where, alongside „modified“ silent and durable asphalt, we find cycle paths, street furniture and elements for road safety. The panorama is completed by design products, objects and new compounds made by combining recycled rubber and thermoplastic materials.

Various treatment lines of this type have been installed by Forrec in different areas of the world and are currently operational. Over time, however, it has been noticed that the supply of granules of this size is much higher than the demand and sometimes the market value does not justify the investment. For this reason, especially in some specific geographical areas, projects aimed at using a shredded rubber granule reduced to a size that can be used by cement plants as a high-yield fuel (given the high calorific value of rubber) are underway. The energy recovery of ELTs represents a fundamental component to ensure 100 % of the virtuous cycle of ELT recovery.

The term TDF (tire-derived fuel) is used to indicate tire fuel. Energy recovery from ELT-derived materials is mainly carried out in cement factories, whose high operating temperatures ensure compliance with emission limits and allow to make the most of the high calorific value of rubber, which is comparable to that of pet-coke.

Moreover, the use of this process allows recovering combustion residues, ashes and steel, as materials, which are incorporated into the finished product, thus avoiding the use of further virgin raw materials, with environmental and economic benefits for companies and the community.

Speaking of WTE, the most delicate phase is that of primary shredding for the production of TDF (tire-derived fuel). This treatment requires that the output product be of well-defined dimensions and with the characteristic of a clean-cut and not frayed. Considering the importance of this waste, Forrec has developed the TX1600 shredder to meet the specific requirements of this market segment, without neglecting productivity and keeping an eye on the relationship with production costs.

(Published in GLOBAL RECYCLING Magazine 1/2021, Page 48, Advertorial, Photo: Forrec srl Recycling Systems)