E-waste Plant and Recycling

Have you ever thought to can make money from electronic waste? There is no doubt that electronic devices are an indispensable part of our lives. All those electronic devices make our lives easier and increase our quality of life. The world cannot ignore the rapidly developing technology.

As a result of those developments, we can see the new models of cell phones, computers, kitchen appliances, air conditioners, televisions, laptops, hard disks, microwaves, etc.. Every product is launched very quickly.

What precious metals are found in electronic wastes?

Precious materials such as gold, silver, copper, platinum, and palladium are used in the process of electronic devices. So, the interest in recycling precious metals from e-waste increases daily.

Is e-waste recycling a profitable investment?

Even though producing and selling technology is a very profitable investment, all those products are open to the recycling and recovery of precious metals used in the production of electronic devices is possible with the application of the right process. But the issue is, what is the right process, and how can you make an e-waste plant. This essay will give you some information about e-waste and e-waste plantations.

Importance of e-waste recycling

Many precious metals are used for manufacturing electronic devices. Precious metals such as gold, silver, copper and palladium in all electronic wastes and scrubs can be recovered. Then what is e-waste? E-waste can be included from mobile phones to modems, computers, televisions, etc. all expired, broken electronic devices can be used in e-waste recycling. There is no doubt that recycling all of those e-wastes is a profitable investment, such as the recycling of precious metals, but at the same time, recycling e-waste is an extremely beneficial investment to protect our nature. All of the expired devices have harmful toxic residues. These electronic wastes often contain toxic chemicals and hazardous materials. That can have extremely harmful effects on wildlife, human health, and the environment. If those are kept in the trash pile, e-waste will damage nature. Therefore, recycling e-waste is an environmentally as well as a profitable investment. Despite technological advances and research, only a small part of e-waste is taken for recycling.

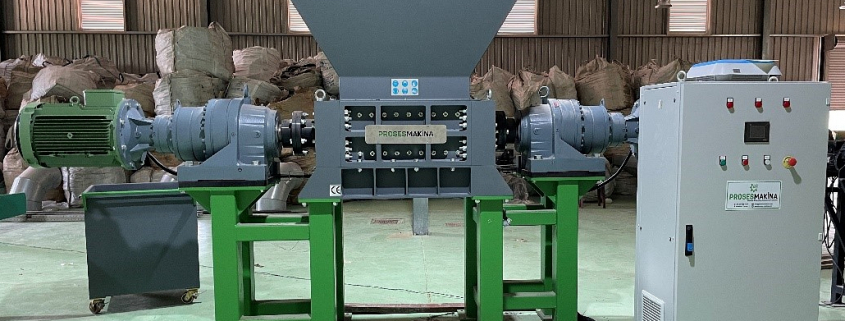

The electronic waste recycling process is a multi-stage process consisting of chemical and physical steps. The physical process includes adjusting the parts to a sufficient size. The electronic wastes for recycling were soldered and held together during production. Worthless materials and iron need to be separated from the electronic wastes. Proses Makina’s component separator is working at a specific working temperature to separate those materials from e-waste. The pieces coming out of the separator are then shredded and converted into a much smaller granular structure, increasing the surface area of the materials.

The materials coming out of the shredder contain dirt and grime. They need to be washed on the shaking table. If the materials are not washed, the efficiency will decrease. Afterward, these parts have to be dried before entering the rotary furnace. The dryers save time and work. The parts coming out of the dryer are now ready to enter the oven for the melting process.

E-waste recycling: A chemical process?

Melted products go to the mold casting unit. Mold casting units are designed for producing anodes for electrolysis units. The mold casting unit has a pre-heating system. The chemical process begins after the casting process is finished. Proses Makina’s chemical process consists of electrolysis, refining and neutralization units. The first step of the chemical process is electrolysis after the mold casting. High purity copper can be recovered from the electrolysis unit. Precious metals and copper are separated into the electrolysis unit. The copper can be collected and then the process continues with refining for the recovery of precious metals. Precious metals such as high purity gold, silver, palladium, and platinum can be obtained. Every precious metal has separate chemical processes. Proses Makina provides technical training.

Proses Makina is a qualified company for planting e-wastes and applying the production of electronic waste facilities with its expert engineer team and advanced machinery. Proses Makina, with its experienced and expert staff in the field of e-waste, with its many facilities that it has established in Iran, India, Sri Lanka, Vietnam, Pakistan, Egypt, Portugal, Spain, America-Virginia, and currently working in different parts of the world. Contact the company to get detailed information about precious metal recycling from electronic waste and to be your solution partner.

Source: Proses Makina (March 17, 2022)