PICVISA Committed to the Circular Fashion Economy

“The equivalent of one garbage truck of textiles is wasted every second, while less than one percent of the clothing is recycled into new clothes”, says a report that informs about a new vision for a circular system.*)

The circular economy model calls for a new textiles economy, in which clothes are designed differently, worn longer, and recycled and reused much more often. Textile reusing and recycling is possible if fabrics are separated – and grouped – according to their composition: cotton, silk, wool or synthetics. Thus, as with other materials (the heterogeneity of fabrics is similar to that of plastics), making a correct classification is essential.

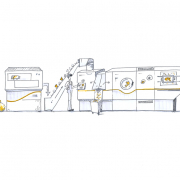

PICVISA is a technology company that offers solutions based on artificial intelligence and vision through its AI-powered computer vision software and hardware. The company can monitor and sort textiles in-feed on moving conveyor belts, ensuring proper separation of several different textile categories.

How can customers use PICVISA AI technology?

PICVISA AI textile recognition system is deployed globally on moving conveyor belts in sorting facilities. By automating textile composition analysis, PICVISA provides waste managers, producers and regulators with actionable insights to increase textile recycling and reuse rates. By building solutions for monitoring, auditing, and sorting of large textile flows, the company contributes to unlocking the linear, which will, in turn, support the transition to a circular economy.

Successful stories

Reducing the cost of manual sampling, enhancing product quality or informing on waste generated end-to-end are among the most common problems affecting Picvisa’s customers.

That is also the case for Coleo Recycling-Col&bri in Galicia (Spain). The textile recycling company was looking to automate the manual sorting of textile fractions into different fractions according to material and color. In response to Coleo Recycling’s need, Picvisa developed a software for detecting textile clothes according to their chemical composition and color. After that, the system transferred them into specific containers. The system can classify up to 24 different materials simultaneously. That means each material is detected and transferred to the right container.

David Puyuelo, Director of Col&bri Partners says, “Thanks to PICVISA, we can process 5,000 tons/year of material collected from industrial and domestic. We can feed piece by piece without previous shredding into an optical unit that identifies and classifies by material and color and separates into up to 24 different outputs. The composition analysis is carried out in continuum and real-time. Thus, creating metrics and data sets that we can use to inform our decision-making on how to optimize the textile selection and sorting processes.” EU legislation plans to start the selective textile recollection before January the 1st, 2025, and to set objectives on how to reuse and recycle this waste. Therefore, cities need to implement new selective collection and selections systems for textile waste. Picvisas’ technology and experience can help meet these objectives and increase the circularity of the textile consumption model.

Check out our linkedin page to see how we perform textile sorting: https://www.linkedin.com/feed/update/urn:li:activity:6863801828241473536/

(Published in GLOBAL RECYCLING Magazine 1/2022, Page 45, Advertorial, Author: Silvia Gregorini, Head of Development at PICVISA, Photo: PICVISA)