Cost-saving Torque Limiter for Direct Drives

To protect – also in the recycling sector – machines and systems from expensive overload damage, safety clutches, overload clutches or torque limiters are used. If an overload in the drive train occurs, the torques set too high can damage or even destroy the drives.

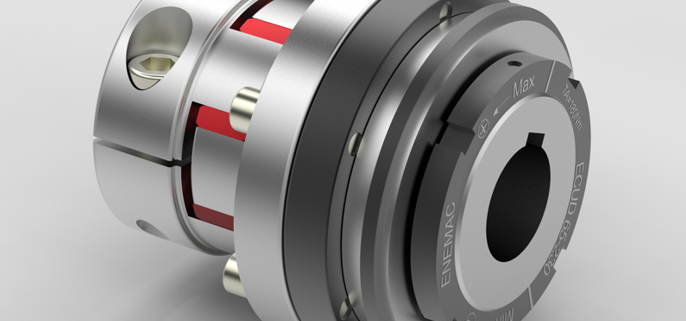

A cost-saving alternative for direct drives is offered by the German company Enemac with the torque limiter type ECUD. According to the company, it is a combination of a torque limiter with a keyway to protect from collisions and a jaw coupling with a clamping hub. The jaw element of the coupling compensates as well splicing as vibrations and acts as electrical isolating, the provider assures. “The type ECUD can compensate axial misalignment of 0.5 – 1 mm and lateral misalignments of 0.1 to 0.15 mm. The torque range is available from 1.8 Nm up to 2000 Nm in 14 different sizes. The hubs can be sized between 6 mm and 90 mm,” Enemac informed. “This coupling offers high torsional stiffness and is free of wear and maintenance. The one-sided mounted, easy to assemble clamping hub joins mandrel and torque limiter free of clearance and force fitting. If required it can also be equipped with a keyway.” Special versions were available on request.

As reported, for demanding environments Enemac also offers this safety coupling as corrosion-resistant variant ECUD_KS. “For this purpose, the main components of the torque limiter are nitro-carburized or gas-nitrided and then oxidized. The built-in disc springs are coated, and screws, balls and bearings are made of stainless steel. That makes the coupling type suitable for many outdoor applications and wherever moisture could become a problem,” the information said.

(Published in GLOBAL RECYCLING Magazine 3/2022, Page 51, Photo: ENEMAC)