Recycling to Create New Value: The Potential of Aluminum and the Innovative Solutions for its Processing

The increasing consumption of resources and the rapid technological change are contributing to a rising need for investment in advanced and material-specific recycling systems.

One of the most valuable materials that can be recycled is aluminum. Indeed, thanks to its characteristics, aluminum is considered a circular material, capable of being recycled multiple times without losing its original properties. Furthermore, its recycling process only requires five percent of the energy needed to produce it primarily, making the process very convenient and attractive.

FOR REC’s commitment to a more efficient aluminum recycling process

FOR REC takes great care of regulations against environmental pollution, designing customized and high-performance machines for the recycling of aluminum and other materials. These solutions allow the treatment of metal to obtain new resources usable for future processes. In addition, the plants are specifically developed to reduce the volume of aluminum and select the most appropriate materials for reuse. The line developed by FOR REC’s internal department has been designed to make the product ready for the furnace, and it is composed of two essential parts:

- Hammer mills: extremely powerful and fast processing, which allow the grinding of heterogeneous materials;

- Single shaft shredder: built with high quality steel, ideal for the treatment of metals.

Hammers mills for aluminum processing

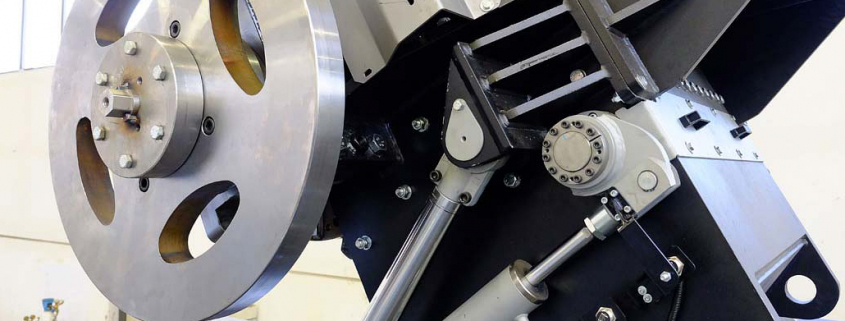

FOR REC hammer mills are realized with a sturdy structure, which make them very trustworthy, and are designed to ease the access to the parts subject to wear and tear, making the maintenance faster.

Main advantages:

- Hydraulic opening system for the upper cover

- Hydraulic lifting of the rotor by means of the upper cover lifting

- Hydraulic opening for the discharge of foreign bodies

- Screen fixed by the upper cover

- Customizable hammers

- Adjustable cutting plates

- Cutting chamber with changeable armours made of anti-wear material

- Special anti-vibrators to reduce stresses on the machine support frame

- Inverter for rotors revolutions control

Single shaft shredder for aluminum processing

Thanks to its enhanced structure and low running rotor, FOR REC single shaft shredder combines the traditional cutting system with a technology based on interchangeable plates equipped with special shock absorber bearing that protects from possible breakdowns. Everything has been designed to ensure maximum reliability, fast maintenance, and considerable production increase.

Main advantages:

- Special steel blade-holder shaft with surface heat hardening to reduce wear

- Belt transmission with chain gearbox in oil bath

- Interchangeable wear-proof selection screen for a fast maintenance

- Spiral lateral seals for a safer working process

- Configurable blades for thickness and number of teeth

The systems designed and manufactured by FOR REC have multiple and customizable solutions according to the kind of material to treat (cast aluminum, UBC bales and aluminum profiles, both loose or baled). Many different installations have already been installed in Italy and all over the world. Turkey represents our top market, with around ten operative systems (single machines or complete lines).

Are you interested in learning more about FOR REC aluminum recycling plants? Visit the company’s website www.forrec.eu.

(Published in GLOBAL RECYCLING Magazine 1/2023, Page 44 -Advertorial-, Photo: FOR REC)