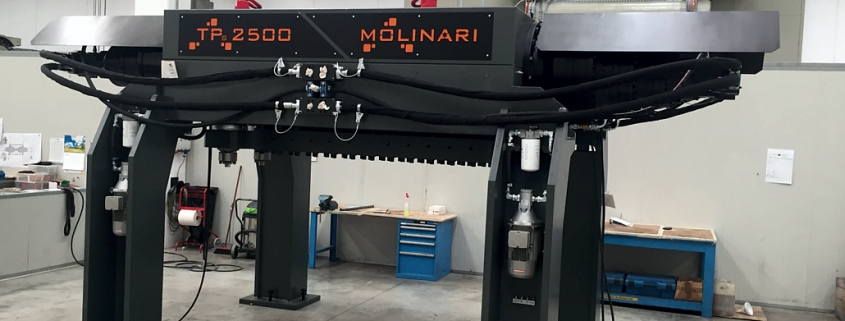

Molinari Installed its Biggest Shredder for Tires in Europe

It was set up in one of the principal plants for ELT in the north of Italy, within an important expansion program.

This time Molinari played at home and was ready to install its biggest shredder of 46 tons in one of the most important Italian realities concretely active in the green economy. The machine is used for shredding End of Life Tires collected by the Ecopneus consortium to prepare them for the following processing phases that make them recyclable.

The order was commissioned in November 2018 during the Ecomondo exhibition in Rimini, and the installation was scheduled for May. It is a double shaft shredder with independent shafts. The central blades are placed on a traverse collocated at the center of the two shafts. One of the most innovative features of this machine is that the distance between rotary and fixed blades can be easily and rapidly adjusted.

Tires are among the most difficult materials to treat: They are made by rubber, harmonic steel and synthetic fiber. The rubber is elastic by definition and the steel very weary, so all you need are sharp blades capable of cutting rather than tearing and high structural rigidity of the machine. These aspects are particularly important when you want to combine the optimization of energy consumption with a clean cut (with few spiders).

The Molinari project was born taking into consideration these characteristics – necessary conditions to face the tire shredding market. The company has decided to make innovations despite the traditional processing schemes. The first innovation concerns the fact of having a screen installed directly on the machine. Thanks to that, the material remains in the grinding chamber until it is reduced to a size that allows its passage through the holes of the screen. The second novelty, the most important, is the one concerning the adjustable cutting system, which makes it possible to recover the millimeters of wear lost during the working operations, keeping productivity and energy saving constantly over time. Rubber is a difficult material to treat because of its elasticity. In fact, it absorbs a lot of energy, transforming it into heat and not into cutting energy. Molinari managed to overcome this problem with an innovative rotor and a new blades design. The blades are trapezoidal and have a thickness of 68 millimeters. They are hardened and can be re-sharpened by 20 millimeters.

These are all aspects that the customer considered a lot before choosing Molinari among a group of factories considered top players in the shredding world. The robustness of the machine also allows treating tires with big dimensions, which could be the object of interesting opportunities to get new market shares.

The shredder is the biggest shredder for tires installed by Molinari in Europe. The country that showed greater interest in the factory from Bergamo was France, a difficult country if we consider that it is the only one which self-regulated to produce shreds (the so-called pieces of shredded tires that come out of the shredders) of quality, classified according to well-defined standards. After the first Molinari shredder was installed for a test phase just to see if it could produce shreds responding to French specifications, three more machines were sold in less than 12 months.

The success was given thanks to the saving in terms of energy consumption but above all by the possibility of having already calibrated output dimensions of the shreds, without the need of adding external screens and bulky recycling systems. For these and many other reasons, the largest TP series shredder for tires produced by Molinari was chosen and requested, seeing also in a short amount of time, the recognition, at a national and international level, of the commitment and work done in the recent years. With this project, Molinari affirms that Italy is also ready to catch up with the other large European and non-European international markets, which see on the one hand the need to manage increasingly important quantities of tires to be ground, on the other they represent an unmissable opportunity to export Made in Italy technology.

____________

Technical specifications:

2500 mm rotors length

860 mm rotors diameter

120 rotary blades

13 fix blades

500 kW rated output

4.0 compliant to the requirements

____________

Photo: Molinari srl

(GR 22019, Page 40-Advertorial)