USA: Eastman will Build a Second Molecular Recycling Facility

In March, the American chemical company Eastman informed that it was selected by the Department of Energy (DOE) as one of 33 companies for award negotiations to support Eastman’s second molecular recycling facility in the USA.

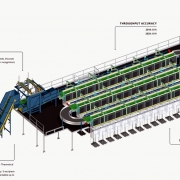

The DOE selection would lead the company, which operates its first molecular recycling facility in Kingsport (Tennessee), to announce intentions to build a second molecular recycling facility in the USA at its location in Longview (Texas). As reported, Eastman selected the Longview site “due to synergies with existing infrastructure and operations, favorable energy supply and footprint, and access to western and central U.S. feedstock pools. The location also provides enough space for onsite renewable energy. The investment includes operations that will prepare mixed plastic waste for processing, Eastman’s next-generation molecular recycling unit to depolymerize waste, and a polymer facility to create virgin-quality materials for packaging and textiles.” The Longview molecular recycling facility would have the capacity to recycle approximately 110,000 metric tons of hard-to-recycle plastic waste.

About the technology

“Eastman’s proven polyester renewal technology recycles hard-to-recycle plastic waste bound for landfill or incineration today”, the press release said. The technology would allow this waste “to be broken down into its molecular building blocks and then reassembled to become virgin-quality material without compromising performance”. By its own account, Eastman is enabling “the potentially infinite use of materials by keeping these valuable molecules in production, in a material-to-material high-yield loop”. Furthermore, the company could transform waste plastic into virgin quality polyesters (suitable for contact with foodstuffs) “with lower greenhouse gas emissions than traditional methods”. In addition to this newly announced facility in Texas, Eastman has recently completed its first molecular recycling facility in Kingsport and plans to invest in another location in France.

Some days earlier, Eastman had informed that it is generating revenue from its molecular recycling facility in Kingsport. The company expected to ramp up production of the facility over the coming months “and enable growth across a wide range of markets”. Achieving this critical milestone would enable the company’s pathway to deliver approximately 75 million US-Dollar of incremental EBITDA (earnings before interest, taxes, depreciation and amortization) in 2024 from this facility “as it builds momentum in its circular economy platform”.

Collaboration with customers

As a global specialty materials company, Eastman employs approximately 14,000 people around the world and serves customers in more than 100 countries. In 2023, the company had achieved a revenue of approximately 9.2 billion US-Dollar.

The company works with customers “to deliver innovative products and solutions while maintaining a commitment to safety and sustainability”.

(Published in GLOBAL RECYCLING Magazine 2/2024, Page 11, Photo: Eastman)