DSM-Niaga Announces Research Collaboration with ECOR

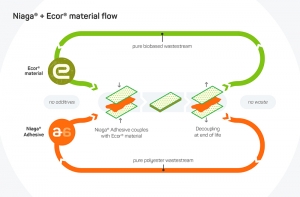

DSM-Niaga has announced that it will start a research collaboration with ECOR, which will focus on developing fully recyclable and healthier alternatives for particleboard, MDF and other panel materials.

ECOR offers technology for circular materials and has an R&D facility in Venlo, the Netherlands. As reported, the two companies have explored a collaboration by combining each other’s technologies. The technology of ECOR can make materials from natural fibers, with water, pressure and heat alone. DSM-Niaga manufactures products by using a reversible adhesive, which enables easy decoupling of different material layers, for full recovery and high value recycling. The combined technologies have been tested in diverse product applications. According to the information, the preliminary results have led to further investigations of applications and will lead to new fully recyclable products.

The ECOR technology is a waste-to-product manufacturing process and results – according to the information – in materials, which enable the circular economy principles of starting with waste resources and enablement of recycling at the end of a product’s life cycle. ECOR material is made of recycled cellulose fibers locally sourced from urban, farm and process waste materials, is completely free of toxins and VOCs and C2C certified.

DSM-Niaga is a joint venture, established in 2014, between the start-up Niaga and Royal DSM, a Dutch-based global science-oriented company active in health, nutrition and materials. The company’s aim is to make products fully recyclable in an easy and affordable way, without compromising on quality or price. Carpet was the first product Niaga redesigned.

www.ecorbenelux.com, www.niaga.world

Photo: DSM-Niaga

GR 12018