Focus on Customers, Quality and Service: Tailor-Made Crushers “Made in Ellerau” by bomatic

bomatic GmbH based in Ellerau near Hamburg supplies the recycling branch with customized shredders for more than 20 years.

One company focus are machines for the shredding of car and truck tires as well as technical rubber. bomatic manufactures machines for the complete process from the pre-crushing through to the granulates. For a long time, bomatic banks on the idea to develop each machine according to the customer’s needs and then build those high-quality machines in Ellerau. Obviously, the company also takes care of maintenance and service.

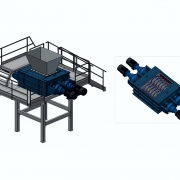

The company has established a successful position for itself in the market by pursuing this strategy. “In the past years, customers had to see for themselves if the crushers, which they bought, are really suitable for their needs. However, nowadays, we build machines our customers are looking for,” explains Marion Böttcher, managing director of bomatic. “The focus on our customers is our strength but at the same time a daily challenge.” For example, the company has designed and build a shredding plant for used tires according to the customer’s needs. Now the customer has a two-level crushing plant which reliably crushes car, truck and tractor tires in palm-sized pieces since the middle of 2018. The facility was planned and built in combination with band conveyors and an electrical control system. The core parts are composed of rotary shears of the type bomatic B1350DD with 2 x 55 kW in the process of pre-crushing and the type bomatic B1000DD with 2 x 22 kW in the process of secondary crushing. However, in the last few years, bomatic did not only produce machines for the crushing of tires but also for other products, that need to be processed. Thus, the company delivered crushing plants for fire extinguishers, zinc die-cast sprues, food waste, renewable raw materials, and many more.

Four different product lines

Nowadays, bomatic relies on four different product lines. Up to today, the rotary shears are one of the most important components of the product portfolio. These shears are available in customizable sizes and designs.

The Unicrex-Granulators – singe shaft machines, which have been developed to granulate pre-crushed solids – are able to granulate, for example, tires, refrigerators or e-waste in very small granulates and prepare these granulates for further recycling.

The Vertical-Shredder Rotacrex has become a popular product since the first launch in 2012 and is available in three different sizes. The machine crushes or opens the material by impact plates in a way they are sortable for the further process. The adjustment of the grain size can be regulated through a slider located at the outlet. Additionally, bomatic offers an extremely robust four-shaft shredder, which especially stands the test within the crushing of hard disks and data carriers. Due to the four-shaft technology, it is possible to integrate a perforated screen underneath the slowly running cutter blocks and thus obtain homogeneous sized granulates.

The company’s performance spectrum encompasses the whole production process from the construction and projecting to the installation through to the initial operation at the customer’s site. Repair work, as well as maintenance, are important parts of bomatic’s business. Therefore, the company has in stock all of the standard wearing parts. Thus, bomatic provides its customers with these parts as quickly as possible. Due to that, the construction of a third hall has been commissioned, of which one half will function as a storage area. Furthermore, there will be enough space for a technical center, which is currently being established.

Moreover, the company already invests in new machines. At the moment a new series, which was constructed for a special case of application, is currently undergoing test operations.

Photo: bomatic

(GR 22019, Page 18-Advertorial)