PUR-Recycling towards a Smart Circular Economy

The European PUReSmart project, which started in January 2019 and will end in December 2022, explores new methods, technologies and approaches in order to transform polyurethane (PU) into a circular material.

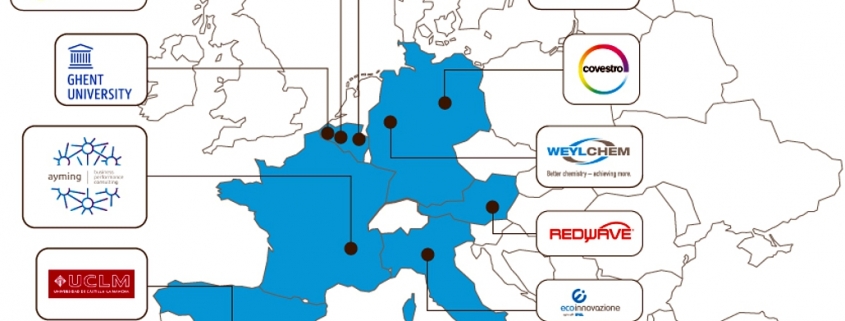

The project consortium consists of nine partners and develops smart sorting technologies to separate a diverse range of PU materials into dedicated feedstocks; these will be broken down into their basic components as inputs for existing PU products, and as raw materials for a newly designed polymer that merges the durability of thermosets with the circularity of thermoplastics.

As reported on the PUReSmart homepage, after twelve months, the consortium could achieve “breakthrough steps”. The development of new chemistries to obtain covalent adaptable polyurethanes (CAPU’s) is moving forward. Also, the work regarding the development of innovative sorting methods is moving ahead.

“The PUReSmart project is working on a process with complete recovery of not only the polyol but also of the isocyanate precursors (amines), which will hopefully lead to the first recycled isocyanate in the world”, the consortium underlined. “The impact of PUReSmart is extremely important in the treatment of End-of-Life (EoL) PU products. As today the recycling options are rather limited, the project will bring new solutions to recover valuable raw materials out of EoL materials to be re-used to make a new generation of CAPU foams. This will close the loop and create opportunities for a circular economy.”

(GR22020, Page 9, Source: Ayming / PUReSmart)