Hammel Recyclingtechnik: End-of-Life Vehicle Recycling – “from Trash to Gold”

What happens to old cars at the end of their useful life?

A car consists of valuable raw materials, 75% metal (steel, copper, light metals, precious metals), besides glass, tires and other plastics. With an unladen weight of one ton, a vehicle consists of approximately 600 kg of steel, 10 kg of cast iron and 90 kg of aluminum. Therefore, at the end of their useful life, vehicles have value as a source of spare parts and for recycling the residual material. In the US alone, approximately 12-15 million vehicles reach the end of their useful life each year, which has spawned a strong dismantling industry.

The car recycling process is quite complex and usually done in two stages. First, all operating fluids, fuel, radiator fluid, engine, transmission and other oils, air conditioning refrigerants, etc. are drained and collected in a dismantling plant. Battery, airbags and catalytic converters are also removed and recycled as spare parts. During the second stage, the residual car body is processed, and a shredder scrap containing iron and steel and a shredder fraction containing non-ferrous metals are obtained.

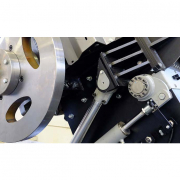

Hammel Recyclingtechnik GmbH has developed a complete mobile metal processing plant for shredding and sorting these materials. A slow-running two-shaft shredder is used at the beginning of the shredding process. The Hammel primary crusher type VB 950 DK – RED GIANT – in a new modern design, is equipped with a powerful CAT C18 stage 5 motor with approximately 563 kW. The input material, such as car bodies or light mixed scrap and white goods, is optimally carried out by the two special counter-rotating shafts.

After shredding, the input material is transported to a mobile metal screen MMS 150 DK. The integrated vibrating finger screen separates the material < 150 mm and > 150 mm. The oversized material is returned to the primary crusher via a return belt to be crushed again. The screened material < 150 mm passes via a vibrating chute onto a magnetic drum, permanently separating ferrous and non-ferrous material. Both materials are discharged via conveyor belts.

For further processing, ferrous parts are fed onto a mobile sorting belt. Manual sorting removes inclusions that may contain waste, cable and stainless steel. An almost unmixed, marketable FE material is produced as the end product.

The non-ferrous parts are sorted into aluminum and shredder light fractions with an eddy current separator. The separator type MWA 1000 E is semi-mobile and installed on a hook lift and has a vibrating chute for optimal feeding of the material onto the fast-rotating permanent magnet system. A time-variable magnetic field induces eddy currents in electrically conductive particles such as aluminum and copper and separates them via conveyor belts. Further integrated sorting tables enable the production of a sorted aluminum fraction in which the manual inclusions are sorted out. The shredder light fraction produced, a mixture of materials such as plastic, rubber, glass and residual metals, is used for energy recovery in waste incineration plants or in landfill construction or mining backfill.

All components of the metal plant are interconnected, and the electrical machines can be operated by an integrated generator installed in the MMS 150 DK screen. The “mobile” plant can be set up at any other location rapidly, which is an advantage.

The main objective of processing end-of-life vehicles with the Hammel plant is to separate different material streams simply and cost-effectively. In total, almost 99 % of the metals contained in end-of-life vehicles can be recycled. If you want to see the Hammel plant live, please visit the next demo day at Hammel in Bad Salzungen or contact the company at: info@hammel.de.

(Published in GLOBAL RECYCLING Magazine 1/2023, Page 46 -Advertorial-, Photo: Hammel Recyclingtechnik GmbH)