Eriez’ Shred1 Achieves Ultra-High Purity Steel From Scrap

At present, vehicles are tightly regulated to limit environmental impact when they are scrapped. This is done through various measures to encourage the recovery, reuse and recycling of metals, plastics and rubber to reduce the amount of waste created. However, beyond the considerations of environmental impact lies huge value for recyclers with the right tools to extract profit.

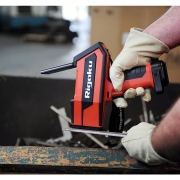

Since introducing the revolutionary Shred1 Ballistic Separator in 2011, Eriez has successfully installed units in various shredding yards, steel mills and slag processing facilities throughout Europe and North America. Other than a few minor modifications made to the design of the unit since its release to further improve maintenance accessibility, the Shred1 has proven itself to be the reliable and effective choice for scrap processors. Those who are looking to differentiate themselves with a premium ferrous shred whilst demanding a higher value per unit weight have found the Shred1 to be an invaluable part of their process line.

The Shred1 separator produces a premium low-copper shred using ballistics to effectively separate iron-rich ferrous from much of the mixed metals and waste material in the post-magnetic drum flow phase of scrap processing lines. The powerful separator delivers three distinct fractions, the first being a high-value, low-copper-content ferrous product. This valuable shred represents more than 70 % of the flow and contains less than 0.2 % of copper. The second fraction represents less than 20 % of the flow and contains mostly mixed metals, copper and aluminium with steel housings or cores. Hand sorting of this fraction can be achieved with relatively few pickers. The final low-volume fraction representing less than 7 % of the flow consists of heavy steel objects and light materials such as fluff, rubber and some wire. This fraction can also be easily picked or sorted.

When the Shred1 Ballistic Separator is combined with an Eriez P-Rex Permanent Rare Earth Magnetic Drum, the entire process is improved further. This system, referred to as the CleanStream Process, recovers more ferrous metals and concentrates 75 % of the post-drum magnet flow into a low-copper premium shred. It also eliminates the need for a scavenger magnet, a Z-box air system and hand-picking the entire flow, ultimately increasing revenue, and reducing overhead for scrap processors worldwide.

However, it is not all about scrap metal, when it comes to the tires, a magnetic drum is used to extract ferrous pieces and metal detectors to identify any stray metal, enabling every part of a vehicle to be repurposed. These intelligent recycling systems ensure that ‘recycled’ does not equate to a loss in quality or quantity for processers and their end customers.

(Published in GLOBAL RECYCLING Magazine 1/2023 -Advertorial-, Page 48, Photo: Eriez)