Panizzolo Recycling Plants for Metal Waste Treatment

Panizzolo recycling offers a refining plant for the recovery of the metallic fraction from mixed waste that allows to obtain a high level of purity of the secondary raw material. The refining plant offers high efficiency on large quantities and flexibility, allowing you to modulate the plants started up based on market changes and always be ready for any eventuality. The refining plant has various benefits and competitive advantages compared to the current products on the market.

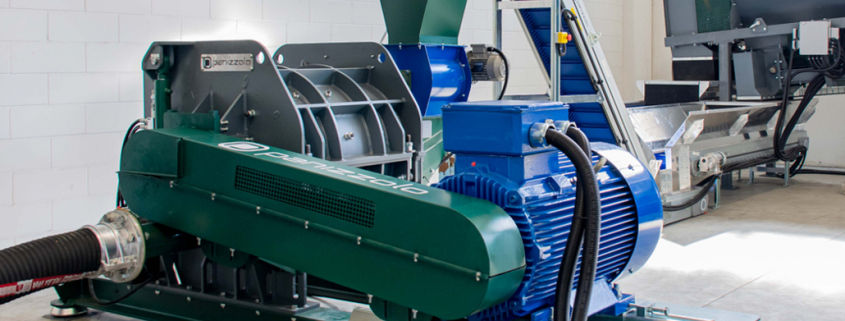

Panizzolo Refining Plant

To address the large quantities of copper-rich metals, aluminum, and brass that are destined for landfills or exported due to the high presence of inert materials within them, Panizzolo has developed increasingly efficient treatment plants over time, capable of recovering even the smallest amounts of metal in-line.

The solutions offered by Panizzolo are the Master Refining Plant and the Refining Islands:

- The Master Refining Plant is flexible and designed for the processing of large batches of material or a continuous standard of mixed waste input. Its in-line setup enables processing in a single production cycle, optimizing energy consumption and maximizing the result of the processed waste.

- The Refining Islands consist of separation and refining treatment modules that allow the customer to optimize energy expenditure, reduce the impact of machine downtime on the plant, and distribute the processing cycle over different timeframes. All of this promotes higher profitability for small waste batches. The design of specific treatment groups that are independent of each other maximizes metal recovery from mixed and highly abrasive waste, offering the possibility of step-by-step processing based on customer needs in terms of production, quality, and quantity. Compared to the Master Refining Plant, the Refining Islands also optimize space more effectively, both logistically and from a production standpoint.

Panizzolo’s refining plant and islands are equipped with technologies and software developed to maximize the profitability of mixed waste treatment, reduce management and personnel costs, and ensure the elimination of non-marketable by-products. Both solutions allow for the processing of mixed waste fractions containing steel and abrasive inert materials, while also recovering even the smallest metallic fractions, resulting in high-quality granules of copper, aluminum, brass, and steel, all the way to complete sorting by commercial type.

The main strengths of Panizzolo’s refining plants are:

- Application Fields

The Panizzolo refining plant is designed to treat materials that are usually difficult to process, such as mixed metal fluff, car fluff, or WEEE fluff. - Prevents Production Downtime

Thanks to Panizzolo’s patented plant elements, the treatment of highly abrasive materials is effective and prevents situations that could cause machine downtime. - Flexibility and Efficiency

All plant elements have multiple adjustments that allow for quick and easy changes in the type of waste input. - End-of-Waste Cycle

Also, thanks to Panizzolo’s patented elements, even materials that are typically difficult to treat are refined, offering excellent output in terms of purity and classifying them as secondary raw materials.

The Panizzolo refining plant maximizes the valorization of mixed waste treatment, bringing great benefits to the environment.

Important components of the plant include:

- Refining Hammer Mills

The valorization of metallic granules is carried out by mills with specific Panizzolo hammers with fusion armor, ensuring component longevity, uniform wear, and higher performance in volume reduction while maintaining consistent metal quality in the output. - Dedicated Separation Systems

The plant employs easily implementable modular technologies managed by a control software for simple maintenance. - Density Separation Tables

Panizzolo density separation tables are low-energy-consumption machines with an easy and quick access during periodic maintenance, resulting in significant time savings.

Output Material Quality

The technological qualities of the Refining Plant and Refining Islands allow for the processing of mixed materials containing abrasive inert substances, which are notoriously difficult to treat and valorize, and over time could reduce the effectiveness of the processing. Through continuous research and development of its refining plants, Panizzolo has created solutions capable of separating even smaller quantities of waste materials such as plastics and inert substances, ensuring that the vast majority of non-marketable by-products are eliminated at the end of the treatment cycle. This results in obtaining only clean metal granules that can be classified as secondary raw materials.

(Published in GLOBAL RECYCLING Magazine 2/2023, Page 46 -Advertorial-, Photo: Panizzolo)