Bonfiglioli’s Complete Range of Solutions for Recycling Processing and Machinery

Bonfiglioli conceives, designs and produces custom solutions for collection, downsizing and sorting of waste materials. Recycling is a key component of waste management to reduce pollution and landfill waste; in order to ensure high-quality operations and the best result in the recycling process, the company provides a complete range of innovative products for Mobile and Industrial Primary shredding solutions.

The company has been active in the recycling industry for a long time, and thanks to various product developments and expansions, the team built a solid reputation in this sector. Now the company offers a complete range of solutions to meet any need in this demanding, crucial sector. The wide range of planetary gearboxes are manufactured in a production process that is firmly focused on the specific needs of Bonfiglioli’s customers. These solutions are developed with the highest levels of customization, which requires right from the initial design phases, in-depth interaction between the customer and the Bonfiglioli team to ensure that all of the required specifications and variants are known for a product that perfectly meets expectations.

That is why the pre-sales and after-sales teams, spread strategically over all continents, play such a crucial role and why ensuring complete support is at the heart of the company’s global success. The product range and its proven reliability are only the starting point of a profitable relationship.

Solutions for recycling plants

From inverters to gear motors and drives, all the components by Bonfiglioli are customized and designed based on the customer’s needs for recycling many different kinds of waste, like tires, metal, paper and plastic. Always with the highest level of customization:

- Primary shredding: Totally integrated machine design and performance are the key features of the planetary products for primary shredding equipment;

- Secondary shredding: A planetary torque rating over 2 MioNm guarantees a complete range of shredding machine applications. Thanks to a high peak load capacity, planetary gears offer best-in-class mechanical performance;

- Conveying: Thanks to an extensive selection of features and space efficiency, Bonfiglioli offers products (such as the F Series and the A Series) for conveying systems. High dynamic response and energy efficiency are signature features. Plus, cost-effective and extended service intervals guarantee low cost of ownership;

- Compactors: An offer of versatile, robust and energy-efficient solutions, such as the C Series, that meet all compactor requirements.

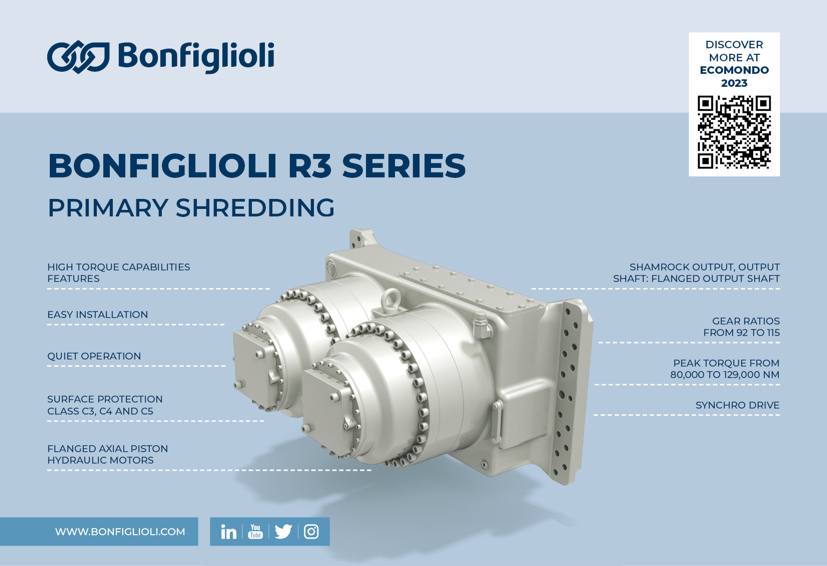

R3 Series

The R3 Series is the perfect range of products for the application in recycling plants and specifically in primary shredding machines. Compact and powerful, their planetary gear train makes them the ideal choice for all severe duty applications where shock loads and impacts are more the rule than the exception. Plus, the configuration is highly flexible, thanks to several options for mounting, gear layout, output shaft and motor interface. So, you can always have a tailor-made solution for your recycling needs. According to the torque needed, R3 Series can be equipped with 1, 2 or 4 hydraulic motor adapter; an electric motor adapter is either available upon request. It features several benefits:

- Easy installation and quiet operation

- High torque capabilities (peak torque from 129,000 to 370,000 Nm)

- Surface protection class C3, C4 and C5

- Gear ratios from 56 to 117

- Synchro drive and axial piston hydraulic motors

Components for stand-alone recycling machines

Bonfiglioli designs and produces custom solutions also for more compact stand-alone machines used for small loads:

- Reverse vending machines: High reliability and long operating life are the stand-out features of the recycling machine products, which are fully integrable with Bonfiglioli drives for a complete package solution;

- Stand-alone shredder: gearmotors, inverters and planetary drives that are reliable and long-lasting

Bonfiglioli believes that product development relies on passion, efficient processes and on the ability to understand customers’ needs. Therefore, first, the company team identifies these needs after an in-depth analysis. Then, through dedicated calculation tools, the team simulates the transmission’s capabilities and performance, allowing it to reduce development time. Ultimately, the alignment stage allows the company to adapt the proposal according to key factors such as performance, installation and maintenance.

bonfiglioli.com/international/en

(Published in GLOBAL RECYCLING Magazine 3/2023, Page 20 -Advertorial-)